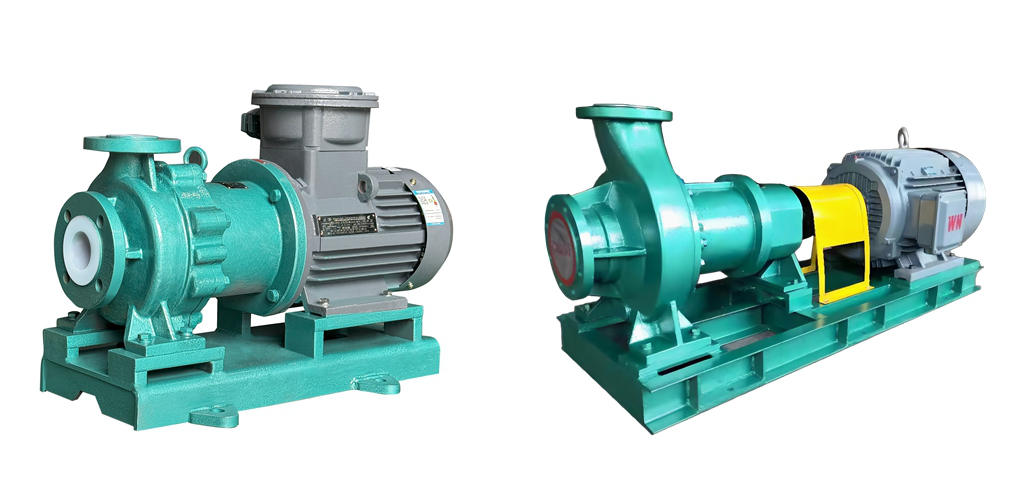

The CYQ High-Temperature Magnetic Drive Pump is specifically designed for chemical applications, featuring high-temperature tolerance and corrosion resistance. It employs a reliable leak-free sealing design for stable and dependable operation, making it suitable for transferring highly corrosive media such as sulfuric acid, hydrochloric acid, and nitric acid. Typically constructed with fluoroplastic lining (PFA/FEP), it safely conveys sulfuric acid of any concentration within a temperature range of -20°C to 180°C.

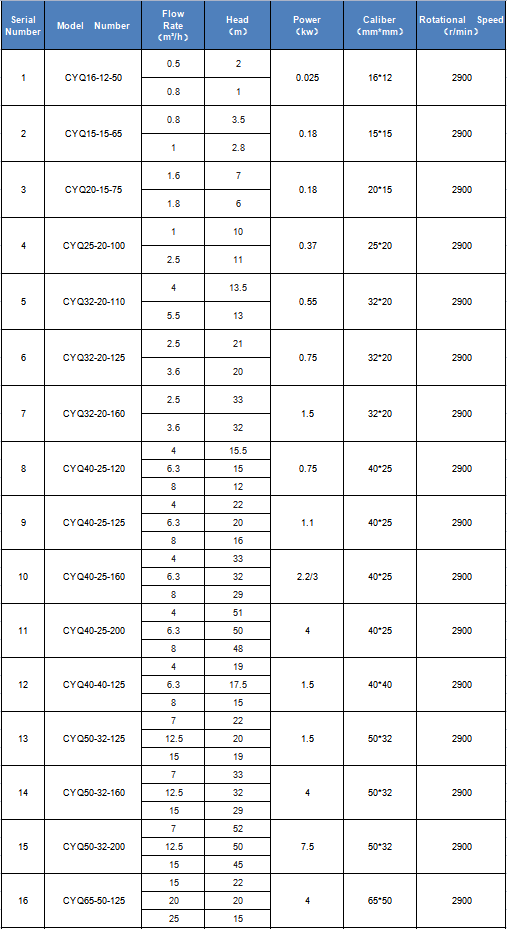

Flow Range :

0.8m³/h~400m³/hHead Range :

5m~130mPower :

2.2kw~110kwTemperature :

-20-180℃Material :

Steel-lined FEP, PFA, PTFECYQ High Temperature Magnetic Drive Pump (also known as Sulfuric Acid Transfer Pump) is a process pump specifically designed for chemical applications. This pump employs advanced magnetic drive technology, utilizing permanent magnets to achieve contactless indirect drive, completely eliminating the leakage risks associated with traditional mechanical seals. When the motor drives the outer rotor (outer magnet) to rotate, magnetic lines of force are transmitted through the isolation sleeve, driving the inner rotor (inner magnet) and impeller to rotate synchronously, thereby achieving efficient liquid transfer.

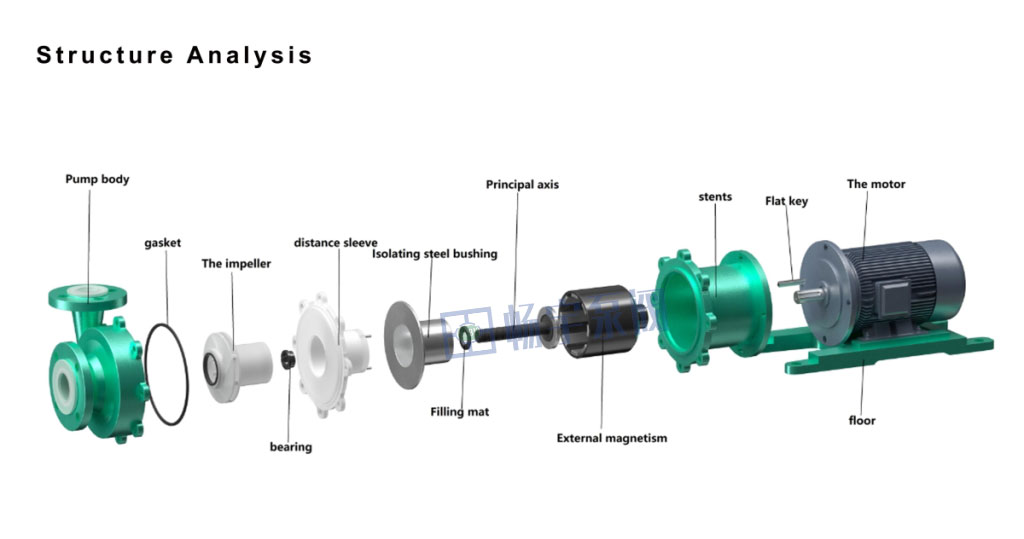

The CYQ high-temperature magnetically driven pump primarily consists of core components including the pump body, impeller, sliding bearings, inner/outer magnetic rotors, and isolation sleeve. Below are the functional characteristics of these core components:

Changyu Pump Industry has over 22 years of experience manufacturing and supplying high-quality magnetic drive pumps, specializing in fluid handling for the chemical industry. As a professional magnetic drive pump manufacturer and supplier, we utilize advanced production equipment, a dedicated technical team, and rigorous quality control procedures to provide customers with reliable solutions.

Our magnetic drive pumps are suitable for handling a wide range of media, including corrosive, toxic, volatile, and high-purity materials, making them ideal for industries such as chemical, pharmaceutical, electroplating, and environmental protection. We also offer custom designs to meet specific operational requirements. Contact us today for a customized quote or technical consultation!

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Magnetic Drive Pump Vs Centrifugal Pump

What is Centrifugal Pump? Parts, Working Principle and Types

Types of Centrifugal Pumps and How to Select

How Does a Centrifugal Pump Operate: Safety Operation Guide

Horizontal vs Vertical Centrifugal Pumps and How to Choose

How Does a Horizontal Centrifugal Pump Work

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)