FGB Series Fluorine Lined Vertical Centrifugal Pipeline Pumps are made of fluoroplastics, with excellent corrosion resistance. It is vertically designed and suitable for pipeline pressurization or circulation in limited space.

Flow Range :

3.6~100m³/hHead Range :

20~32mPower :

1.5~15KwTemperature :

-20-120℃Material :

WCB, HT200, HT250, 304, 316, 316L, 2205Vertical Centrifugal Pipeline Pumps are a highly efficient pump type directly connected to pipelines. Featuring a vertical structural design with inlet and outlet ports aligned on the same centerline, they offer convenient installation and a compact footprint. Their fundamental principle involves an electric motor driving the impeller to rotate at high speeds, imparting energy to the liquid through centrifugal force and continuously conveying it into the pipeline system. This pump is widely used in industrial and municipal water supply/drainage, HVAC circulation, fire protection boosting, landscape irrigation, as well as liquid transfer in chemical, petroleum, and power industries. If you are seeking a pumping solution tailored to your specific application, please contact our professional team for customized proposals and quotations.

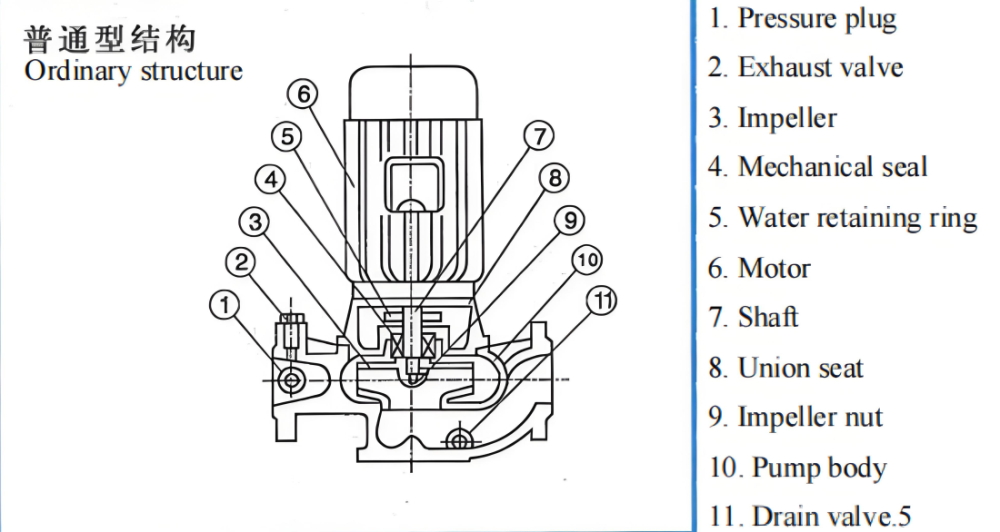

The Vertical Centrifugal Pipeline Pump consists of main components including the pump body, impeller, motor, and mechanical seal. The impeller is directly mounted on the motor's extended shaft, featuring a compact axial dimension for stable operation. The inlet and outlet ports share the same diameter and are aligned on the same centerline, facilitating installation within piping systems. The sealing assembly employs a wear-resistant mechanical seal, ensuring extended service life and convenient maintenance.

After the motor starts, it drives the pump shaft and impeller to rotate at high speed. Liquid enters through the center of the impeller and is flung outward by centrifugal force. It then converts into pressure energy within the volute or guide passages, propelling the liquid toward the outlet to achieve stable flow rate and head. Simultaneously, the pressure at the impeller's center decreases, creating a vacuum zone that continuously draws in fresh liquid. This enables continuous fluid conveyance, effectively elevating the medium's pressure to accomplish long-distance or high-rise water supply tasks.

Based on different media and operating conditions, vertical single-stage pipeline centrifugal pumps have evolved into multiple series:

Changyu is a professional Vertical Centrifugal Pipeline Pumps manufacturer and wholesale supplier Our factory is equipped with advanced production lines, precision testing equipment, and a skilled technical. We have rich industry experience and flexible customization options, can provide pumps tailored to different applications, including water supply, HVAC, firefighting, chemical processing, and more. If you are looking for a trusted pumps supplier in China, please feel free to contact our professional team for detailed solutions and quotations.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

Pipelines commonly use several types of pumps, including:

These pumps are selected based on the type of fluid, flow rate, and specific pipeline requirements.

An inline centrifugal pump is a type of pump where the inlet and outlet are aligned in the same straight line. This design allows for easy integration into existing piping systems without requiring significant alterations. Inline centrifugal pumps are commonly used for circulating liquids in HVAC systems, water supply, and various industrial applications. They are efficient for handling low-viscosity fluids and are known for their compact size and ease of maintenance.

The most commonly used pumps for transporting oil through pipelines are positive displacement pumps and centrifugal pumps. Positive displacement pumps are preferred for their ability to handle high-viscosity oils and provide consistent flow rates. Centrifugal pumps are also used, especially for low-viscosity oils, due to their efficiency and ability to move large volumes of liquid quickly. The choice of pump depends on the type of oil, viscosity, and specific pipeline requirements.

Centrifugal pumps are widely used in various applications, including:

Their versatility and efficiency make them suitable for many liquid handling applications.

The two main types of centrifugal pumps are:

Single-Stage Centrifugal Pumps: These pumps have one impeller and are used for applications that require low to moderate pressure. They are simple in design and suitable for transferring water or low-viscosity liquids.

Multi-Stage Centrifugal Pumps: These pumps have multiple impellers (stages) and are designed to generate higher pressure. They are used in applications such as boiler feedwater, high-rise building water supply, and irrigation systems.

Both types are widely used in various industries for fluid handling.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)