Sep 25, 2025

Magnetic drive pumps (commonly referred to as magnetic pumps) are sealed pumps that transmit power through magnetic coupling. They are suitable for highly corrosive, flammable, volatile, or high-purity media. Their advantages include excellent sealing performance and safety and environmental friendliness. However, they also have limitations such as efficiency constrained by magnetic coupling and susceptibility to wear in the isolation sleeve. If you wish to gain a deeper understanding of magnetic drive pumps—including their operating principles, detailed structure, application scenarios, performance advantages, common issues, and maintenance techniques—please continue reading below.

Working Principle of Magnetic Drive Pump

Magnetic drive pumps operate based on the principle of magnetic coupling. When the motor drives the outer magnetic rotor to rotate, the magnetic field generated by the outer rotor is transmitted through an air gap to the inner magnetic rotor. The inner rotor is connected to the impeller, which rotates under magnetic force, driving the impeller to convey liquid. Since there is no physical contact between the outer and inner magnetic rotors, magnetic force transmission replaces traditional mechanical seals, eliminating leakage issues caused by seal wear.

This design makes magnetic drive pumps particularly suitable for applications requiring liquid leak prevention, transporting highly corrosive, flammable, volatile, or high-purity media. The absence of mechanical contact throughout the process reduces wear, effectively enhancing system stability and safety.

The Following Is Its Operational Sequence:

1. Motor Start-up: Upon energization, the motor commences operation, driving the outer magnetic rotor to rotate.

2. Magnetic Coupling Transmission: The outer magnetic rotor generates a rotating magnetic field, which is transmitted to the inner magnetic rotor through the isolation sleeve.

3. Impeller Drive: The inner magnetic rotor is tightly connected to the impeller. Under magnetic force, they rotate synchronously, propelling the liquid flow.

4. Liquid Intake and Discharge: The impeller's rotation generates centrifugal force, drawing in liquid at the inlet, accelerating it, and discharging it through the outlet, creating a stable fluid transfer process.

5. Sealing and Leak Prevention: The isolation sleeve separates the inner and outer magnetic rotors, eliminating mechanical shaft penetration and avoiding leakage risks associated with traditional mechanical seals.

6. Cooling and Lubrication: Some pump designs incorporate cooling circuits that utilize the conveyed medium to cool and lubricate bearings and the isolation sleeve, ensuring long-term stable operation.

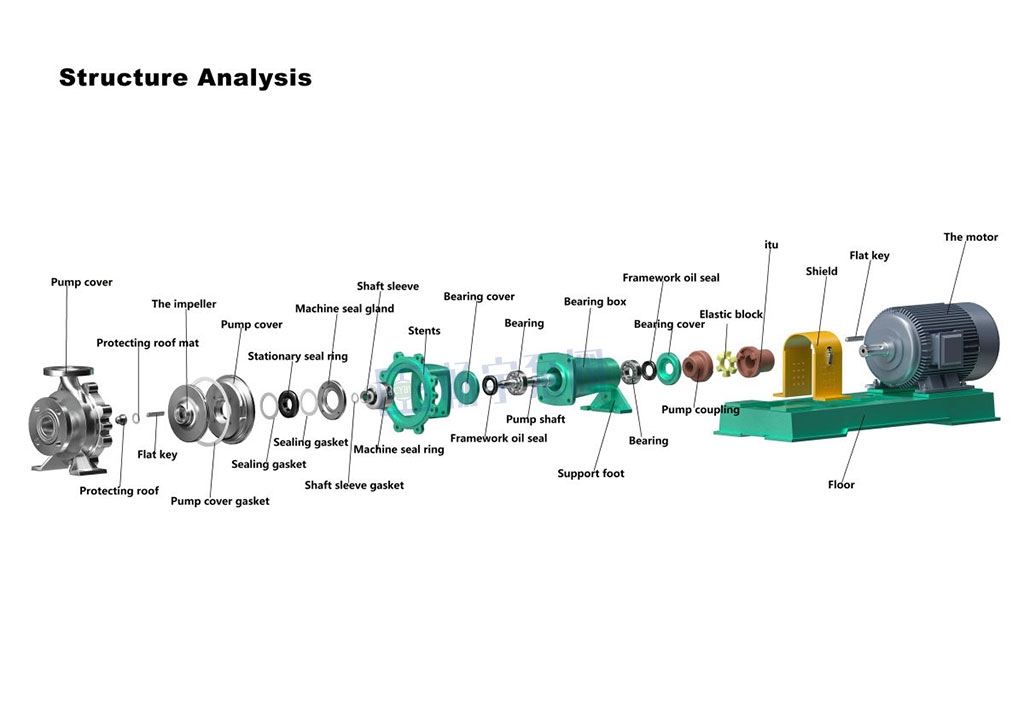

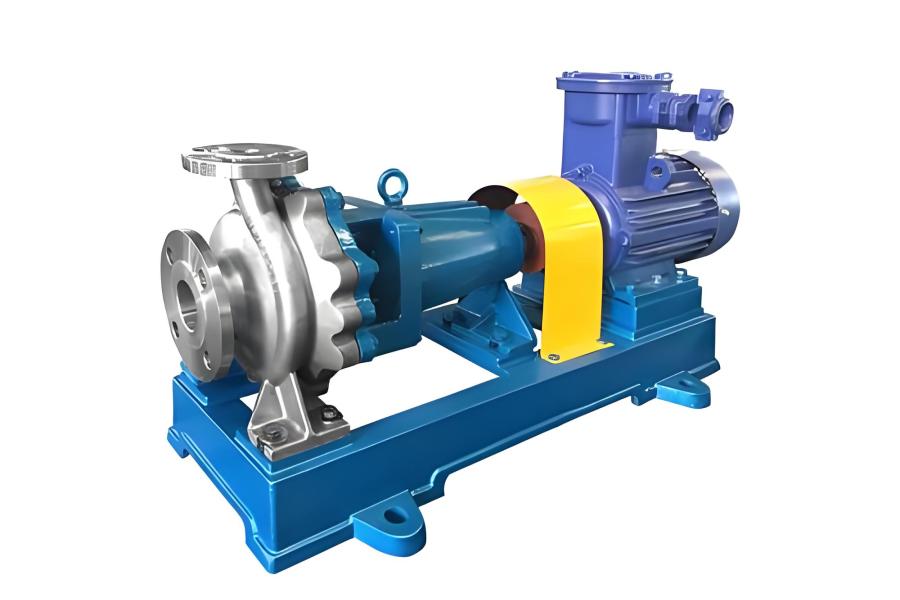

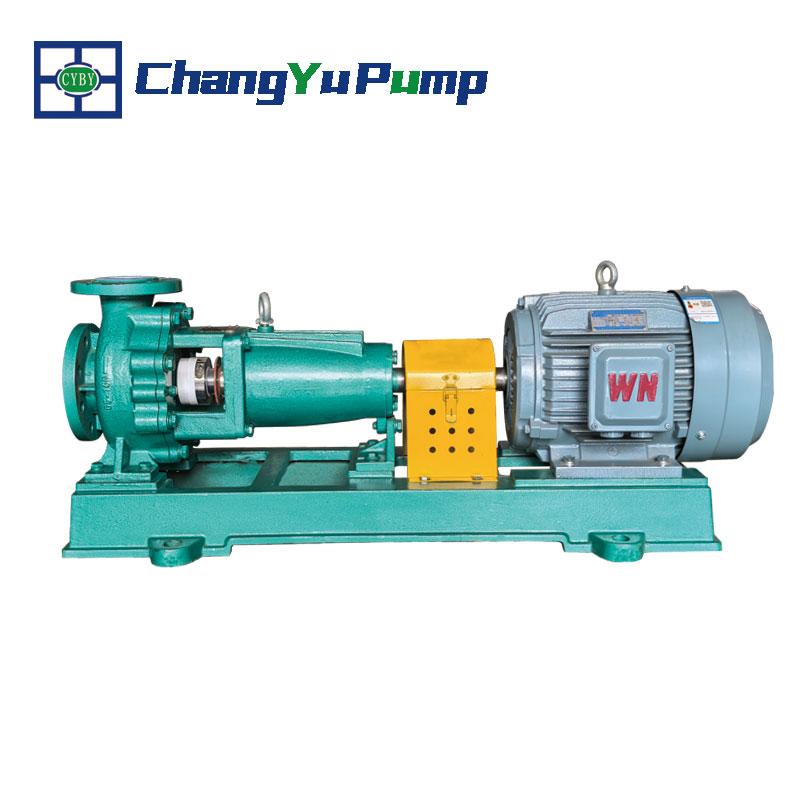

Magnetic Drive Pump Parts

1. Pump Housing: Protects internal components while supporting and securing all parts.

2. Impeller: Rotates and accelerates to convey liquid.

3. Outer Magnetic Rotor: Driven by the motor, generates a magnetic field and couples with the inner magnetic rotor to transmit power.

4. Inner Magnetic Rotor: Couples with the outer magnetic rotor, transmitting power through magnetic force generation.

5. Isolation Sleeve: Constructed from non-magnetic material, it isolates the inner and outer magnetic rotors to prevent fluid leakage.

6. Electric Motor: Supplies power to the magnetic drive pump, driving the outer magnetic rotor's rotation to initiate pump operation.

Magnetic Drive Pump Uses

Magnetic drive pumps are primarily used for conveying corrosive, flammable, volatile liquids, or those requiring high purity. Since they operate without mechanical seals, they effectively eliminate leakage. These pumps are widely employed in chemical processing, pharmaceutical manufacturing, food processing, environmental treatment, and the electronics industry, proving particularly suitable for transporting liquids with stringent safety and hygiene requirements.

Advantages and Disadvantages of Magnetic Drive Pumps

Advantages: Magnetic drive pumps utilize magnetic coupling to eliminate mechanical seals, thereby avoiding the common seal leakage issues found in traditional centrifugal pumps. This significantly reduces leakage risks and makes them suitable for transporting corrosive, flammable, or high-purity liquids. Additionally, they operate smoothly, require minimal maintenance, offer high adaptability, and can substantially enhance system safety and reliability.

Disadvantages: Magnetic drive pump efficiency is constrained by magnetic coupling, and its performance in handling high-viscosity liquids is limited. Due to wear between the inner and outer magnetic rotors, the isolation sleeve requires periodic replacement, increasing maintenance costs. Furthermore, they are relatively expensive and typically suited for specialized applications with stringent safety requirements.

Magnetic Drive Pump Maintenance

Maintenance of magnetic drive pumps primarily involves regular inspections of the magnetic drive system, isolation sleeve, lubrication, and cooling systems. To prevent fluid leakage and ensure proper pump operation, the isolation sleeve should be inspected and replaced periodically.

Additionally, the magnetic drive system must be kept clean to prevent damage to the magnetic rotor. The lubrication system should maintain proper oil levels and cleanliness to avoid overheating or dry running, which can impair pump efficiency and lifespan. Regular system inspections and maintenance effectively enhance operational stability and extend equipment service life.

Magnetic Drive Pump Issues

The primary problems with magnetic drive pumps include the following: First, magnetic coupling limits the pump's operational efficiency, making it unsuitable for conveying high-viscosity liquids. Second, friction between the inner and outer magnetic rotors causes wear on the isolation sleeve, necessitating regular inspection and replacement to prevent leakage risks. Finally, magnetic drive pumps carry a higher price tag. While offering robust sealing performance and safety, their maintenance costs and relatively high price point make them more suitable for specific applications with stringent safety requirements.

FAQS

1. What are the different types of magnetic drive pumps?

Magnetic drive pumps are primarily categorized into the following types based on application requirements and structural design:

1. External rotor magnetic drive pumps: The external rotor is directly connected to the motor, suitable for applications requiring medium to low flow rates and high pressure.

2. Internal rotor magnetic drive pumps: The internal magnetic rotor is directly connected to the impeller, suitable for applications requiring higher flow rates and greater head. Commonly used in chemical and pharmaceutical industries.

3. Side-flow magnetic drive pumps: The pump body structure allows liquid to flow along the side of the pump, typically used for conveying corrosive or high-viscosity liquids.

4. High-Temperature Resistant Magnetic Drive Pump: Constructed from heat-resistant materials, it operates stably at elevated temperatures and handles high-temperature media.

5. Corrosion-Resistant Magnetic Drive Pump: Manufactured from corrosion-resistant materials (e.g., stainless steel or fluoroplastics), it conveys highly corrosive liquids.

These diverse magnetic drive pump types, differing in materials, structure, and operation, meet varied conveying demands across industries, delivering more efficient and safer solutions for industrial environments.What Is The Difference Between Magnetic Drive Pumps And Centrifugal Pumps?

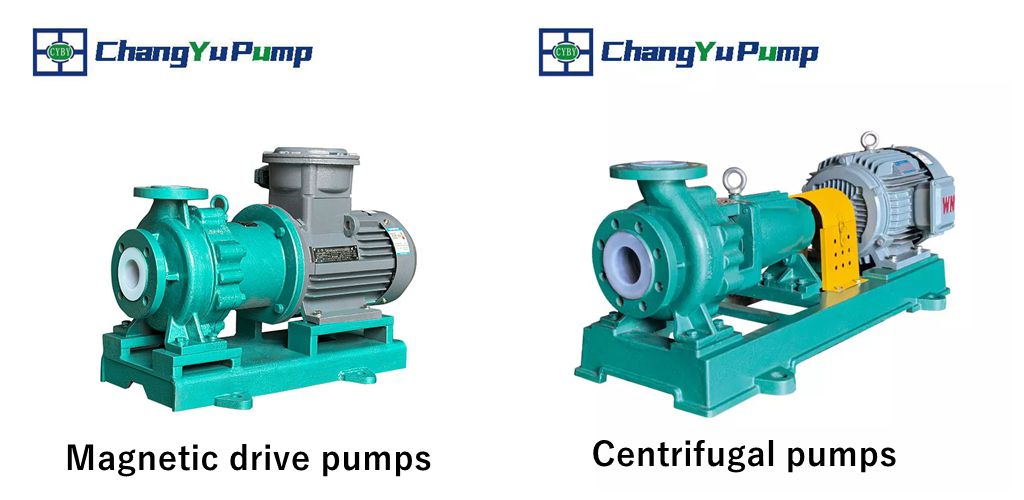

The primary distinction between magnetic drive pumps and centrifugal pumps lies in their drive mechanisms and seal designs. Magnetic drive pumps transmit power through magnetic coupling, eliminating the need for traditional mechanical seals. This design prevents leakage issues, making them ideal for conveying corrosive, flammable, or high-purity liquids.

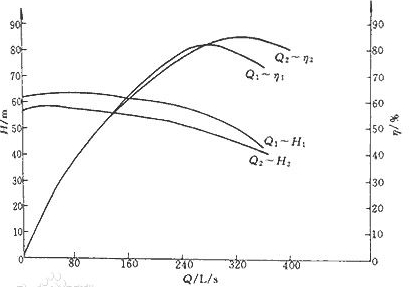

In contrast, centrifugal pumps use an electric motor to directly drive the impeller's rotation, relying on mechanical seals to prevent liquid leakage. This approach carries inherent leakage risks, particularly when handling specialized media. Magnetic drive pumps operate more smoothly and require simpler maintenance, making them ideal for applications demanding high sealing integrity. Centrifugal pumps, meanwhile, are widely used for conveying ordinary liquids with high flow rates and low pressure requirements.

What Are The Advantages Of Magnetic Drive Pumps?

The primary advantage of magnetic drive pumps lies in their leak-free design. Unlike traditional pumps that rely on mechanical seals and may pose leakage risks, they are particularly suitable for transferring corrosive, flammable, or high-purity liquids. They transmit power through magnetic coupling, reducing wear and maintenance requirements while enabling long-term stable operation. This effectively enhances system safety and reliability. The absence of mechanical seals also grants magnetic drive pumps superior corrosion resistance and extended service life. Consequently, selecting this technology enables more environmentally friendly, secure, and efficient liquid transfer operations.The above provides a comprehensive explanation of how magnetic drive centrifugal pumps operate. If you require the transfer of liquids with stringent sealing requirements and prioritize operational safety during production, magnetic drive pumps represent an excellent choice. For any technical inquiries or selection assistance, please contact our team. We will provide customized solutions tailored to your needs. We look forward to hearing from you!

Read More