In industrial production, horizontal centrifugal pumps are used for liquid transfer. They serve as core equipment in water supply systems, HVAC, industrial cooling, fire protection systems, chemical processes, irrigation, and wastewater treatment. Typically requiring continuous operation and consuming significant power, the rational and economical selection and use of horizontal centrifugal pumps are crucial for ensuring efficient and stable system operation while reducing energy consumption and maintenance costs.

This article will provide a detailed analysis of the basic structure and working principle of horizontal centrifugal pumps, helping you gain a deeper understanding and utilization of them.

A horizontal centrifugal pump is a fluid transfer device widely used in industrial applications, characterized by its horizontally arranged pump shaft. It converts mechanical energy into fluid kinetic and pressure energy through centrifugal force, enabling liquid lifting, pressurization, and transportation. Due to its compact structure, smooth operation, easy maintenance, and high efficiency, the horizontal centrifugal pump has become an indispensable key piece of equipment in modern industrial production.

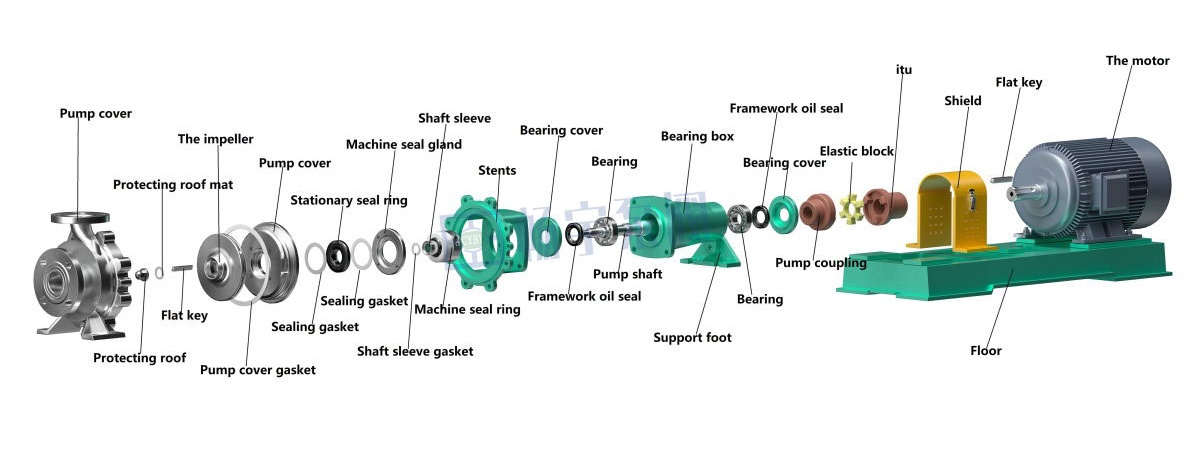

A horizontal centrifugal pump primarily consists of the following core components:

Impeller: The pump's core working component. Typically equipped with 4 to 12 backward-curved blades fixed to the pump shaft, it rotates at high speed driven by an electric motor. Its function is to directly transfer mechanical energy to the liquid, serving as the pump's energy supply unit. The shape, dimensions, and material of the impeller directly impact the pump's performance and efficiency.

Pump Casing: Usually designed as a volute casing, it surrounds the impeller externally. It serves two primary functions: collecting the liquid ejected at high speed from the impeller and, through its uniquely designed gradually expanding flow cross-section, efficiently converting the liquid's kinetic energy into static pressure energy. The casing features a suction inlet at its central top, connecting to the suction piping, and a discharge outlet on its side, connecting to the discharge piping.

Pump Shaft: Transfers power, connecting the motor to the impeller to enable high-speed rotation.

Mechanical Seal / Packing: Located where the shaft exits the casing, preventing high-pressure fluid leakage while blocking air ingress to ensure efficient operation.

Bearing: Supports the pump shaft, reduces rotational friction resistance, and bears radial and axial loads to ensure smooth pump operation.

Suction and Discharge Piping: The suction line typically incorporates a non-return foot valve at its end to ensure the pump and suction pipe are filled with liquid before startup, preventing air lock. The discharge line is equipped with a control valve to regulate flow rate and pressure.

Horizontal centrifugal pumps operate by imparting centrifugal motion to liquid through a high-speed rotating impeller, converting mechanical energy into kinetic and pressure energy. After gaining energy within the impeller, the liquid flows into the volute-shaped pump casing where its velocity decreases. Part of the kinetic energy is further converted into static pressure energy, ultimately forming a stable high-pressure output. Simultaneously, a low-pressure zone forms at the impeller inlet, drawing in liquid continuously through pressure differential to achieve uninterrupted medium conveyance.

Horizontal centrifugal pumps feature relatively simple structures and operating principles, making them widely applicable in industrial fluid conveyance. A thorough understanding of its structural components and operational principles is fundamental for proper equipment selection, achieving efficient and economical operation, and timely troubleshooting. If you require a horizontal centrifugal pump tailored to specific operating conditions, or have any questions regarding pump technology, selection, or maintenance, our professional technical team stands ready to assist. Contact our technical team today for expert solutions and consultation services.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)