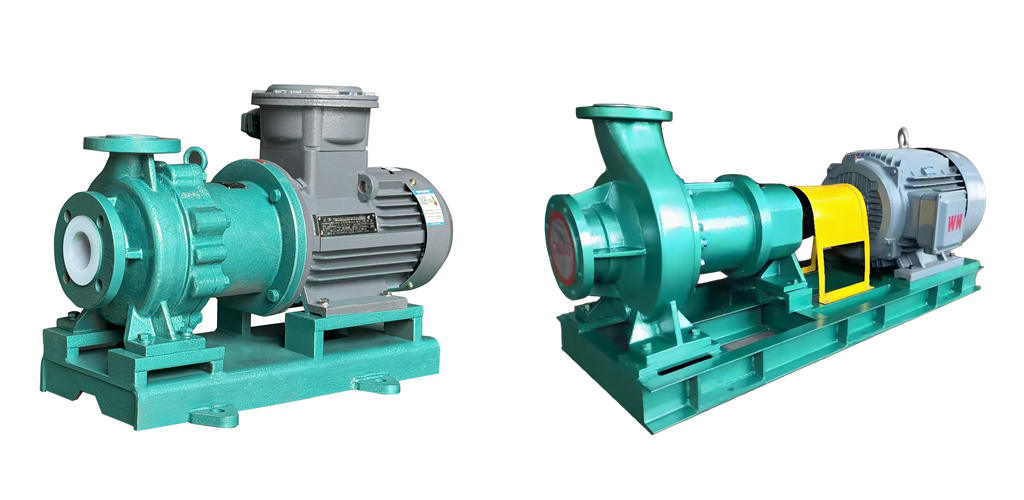

The CYQ-Sulfuric Acid Magnetic Drive Centrifugal Pump features fully fluorinated plastic (PTFE/PFA) flow components, offering exceptional corrosion resistance. It safely handles any concentration of strong acids (such as sulfuric acid, hydrochloric acid, nitric acid), strong alkalis, strong oxidizers, and organic solvents, with an operating temperature range of -20°C~165°C.

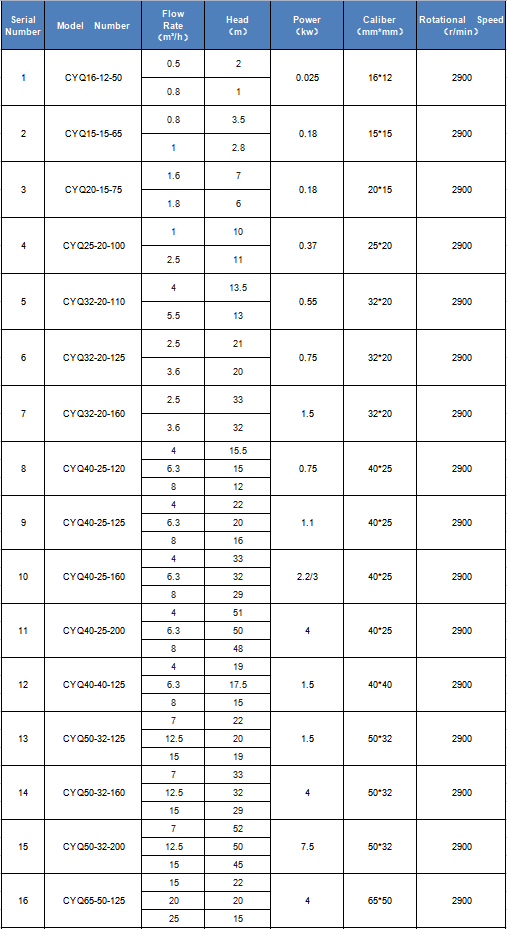

Flow Range :

0.8~400m³/hHead Range :

5m~130mPower :

2.2kw~110kwTemperature :

-20°C~165°CMaterial :

Steel lined with FEP, PFA, PTFEThe CYQ-Sulfuric Acid Magnetic Drive Centrifugal Pump features a seal-less design driven by a magnetic coupling, effectively eliminating the risk of leakage. It is suitable for the transportation of toxic, flammable, and high-purity media, and meets environmental requirements such as EPA and RoHS.

The sealless magnetic drive pumps offer advantages such as low noise, lightweight construction, maintenance-free operation, and a long service life, making it widely applicable in industries such as chemicals, electroplating, semiconductors, environmental protection, and pharmaceuticals. Customized configurations are available, including explosion-proof certification, food-grade materials, and intelligent control systems, providing you with a safe, efficient, and leak-free fluid transfer solution.

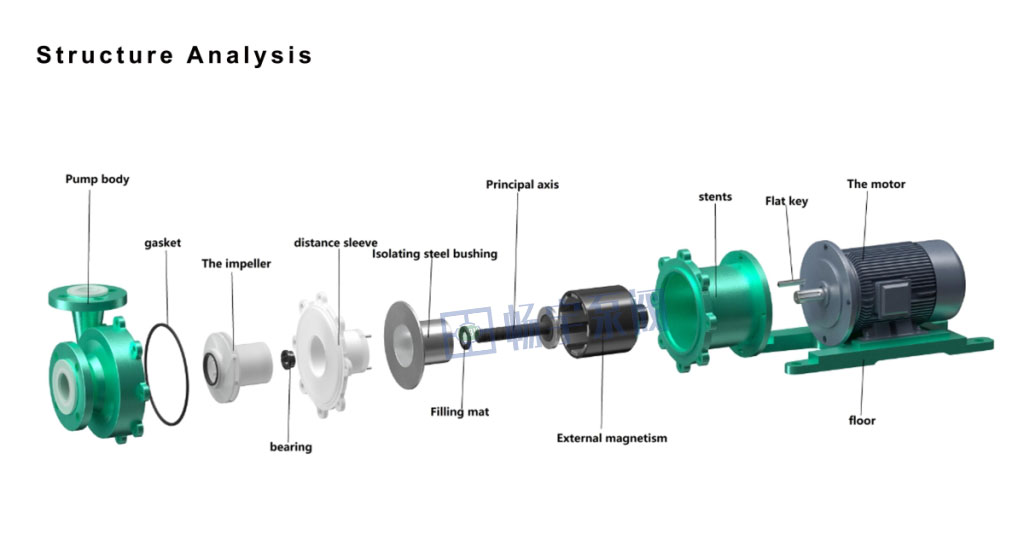

The CYQ centrifugal magnetic drive pump is a chemical process pump that applies modern magnetic drive principles and uses permanent magnets to achieve contactless indirect drive. When the motor drives the outer rotor (i.e., the outer magnet) assembly to rotate, the magnetic field causes the magnetic lines of force to pass through the isolation sleeve, driving the inner rotor (i.e., the inner magnet) assembly and impeller to rotate synchronously.

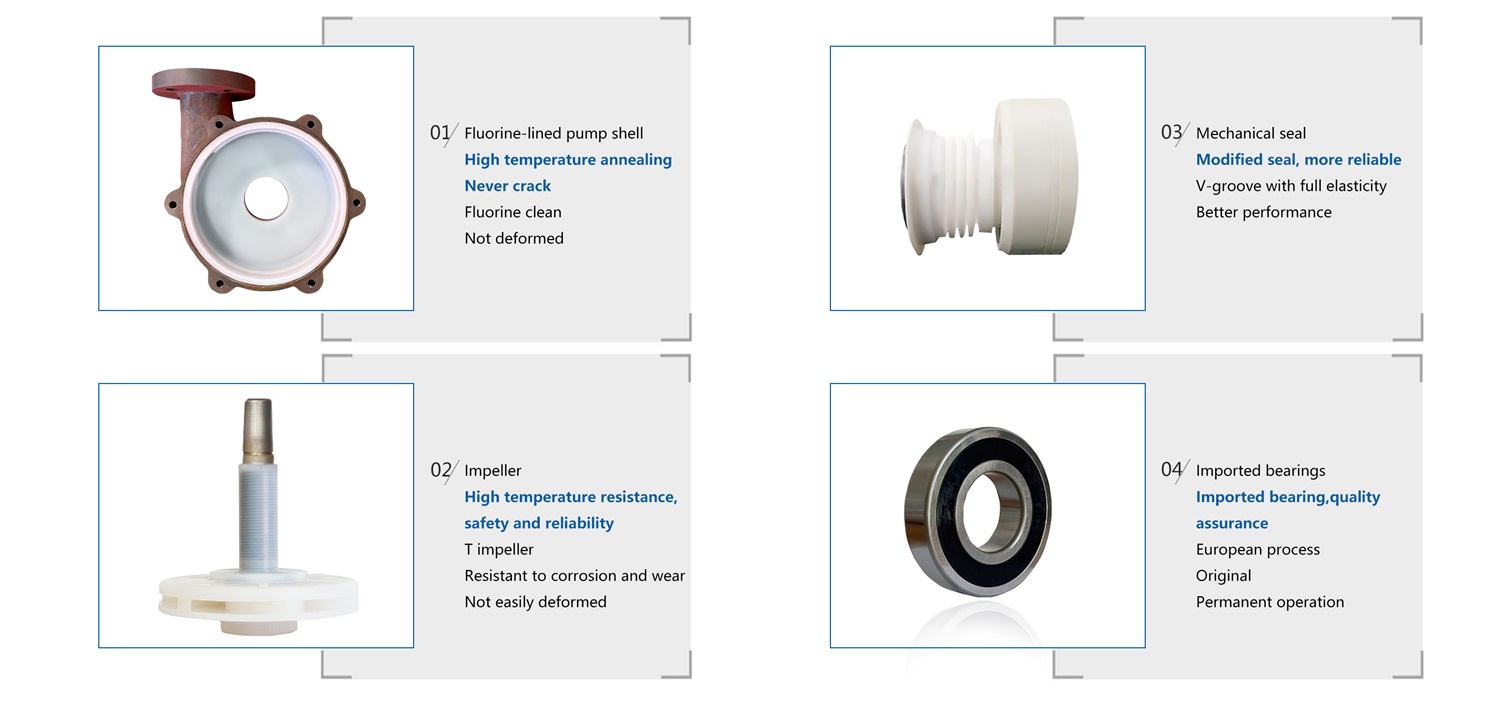

Fully fluorinated plastic corrosion-resistant structure

All flow-through components are made from “the king of plastics” fluorinated plastic (PTFE/PFA) through integral molding, capable of withstanding long-term corrosion from any concentration of strong acids (sulfuric acid/hydrochloric acid/nitric acid), strong alkalis, organic solvents, and strong oxidizing agents. The operating temperature range is -20°C to 120°C (high-temperature models can reach 150°C).

Zero-leakage magnetic drive technology

Special materials are used to achieve fully sealed transmission, eliminating the leakage risk associated with mechanical seal pumps. This technology is particularly suitable for the transportation of toxic, flammable, explosive, and high-purity media.

Enhanced isolation sleeve design

An innovative special alloy/ceramic composite material isolation sleeve is used, featuring ultra-high mechanical strength and electromagnetic conductivity. This effectively eliminates magnetic eddy current losses and improves pumping efficiency.

Leak-free and pollution-free

This new fully sealed industrial pump features leak-free, pollution-free, and energy-efficient characteristics, making it an ideal pump type for creating “leak-free workshops” and production processes.

1. Chemical and Pharmaceutical Industry

Strong Acid/Alkali Production: Suitable for the circulation and transportation of corrosive media such as 98% concentrated sulfuric acid, 32% hydrochloric acid, and 50% liquid alkali.

Pharmaceutical Intermediates: Contamination-free transportation of high-purity hydrofluoric acid and organic solvents (DMF, acetone).

Pesticide Synthesis: Zero-leakage handling of highly toxic media such as chlorinated compounds and organophosphorus compounds.

2. Electronics and New Materials Industry

Semiconductor Manufacturing: High-precision transportation of etching solutions (HF/HNO₃ mixtures) and developing solutions (TMAH)

Photovoltaic Industry: Silicon material acid washing (HCl/HF acid mixtures) and liquid control in solar cell manufacturing processes

Rare Earth Extraction: Corrosion-resistant pumping of P507 extractants and concentrated nitric acid rare earth solutions

3. Environmental Protection and Surface Treatment Industry

Electroplating/Anodizing: Closed-loop circulation systems for hazardous electroplating solutions such as chromic acid and cyanide copper

Acid washing wastewater treatment: Recovery and neutralization of waste acid containing heavy metals such as iron and nickel

Exhaust gas purification: Urea solution for SCR denitrification systems and circulation liquid for alkali spray towers

4. Energy and Military Industries

Nuclear Fuel Processing: Transport of uranium ore leaching solutions (H₂SO₄ system) and spent fuel reprocessing media

Lithium-ion Battery Production: Explosion-proof transport of NMP solvents and lithium hexafluorophosphate electrolytes

Rocket Propellants: Military-grade sealed transport of flammable and explosive media such as hydrazines and nitrogen tetroxide

As a leading manufacturer of magnetic drive centrifugal pumps in China, Changyu Pump has over 22 years of R&D and production experience, specializing in providing leak-free, corrosion-resistant, and energy-efficient fluid handling solutions for the chemical, pharmaceutical, electronics, environmental protection, and energy industries. Our core strengths include:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

What is Centrifugal Pump? Parts, Working Principle and Types

Types of Centrifugal Pumps and How to Select

How Does a Horizontal Centrifugal Pump Work

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)