The centrifugal seawater pump is a single-stage, single-suction, cantilevered centrifugal pump designed in accordance with ISO standards. This pump is specifically designed for the efficient handling of seawater, brackish water, saltwater, alkaline, and mildly corrosive liquids, as well as other fluids with physical and chemical properties similar to freshwater and free of solid particles.

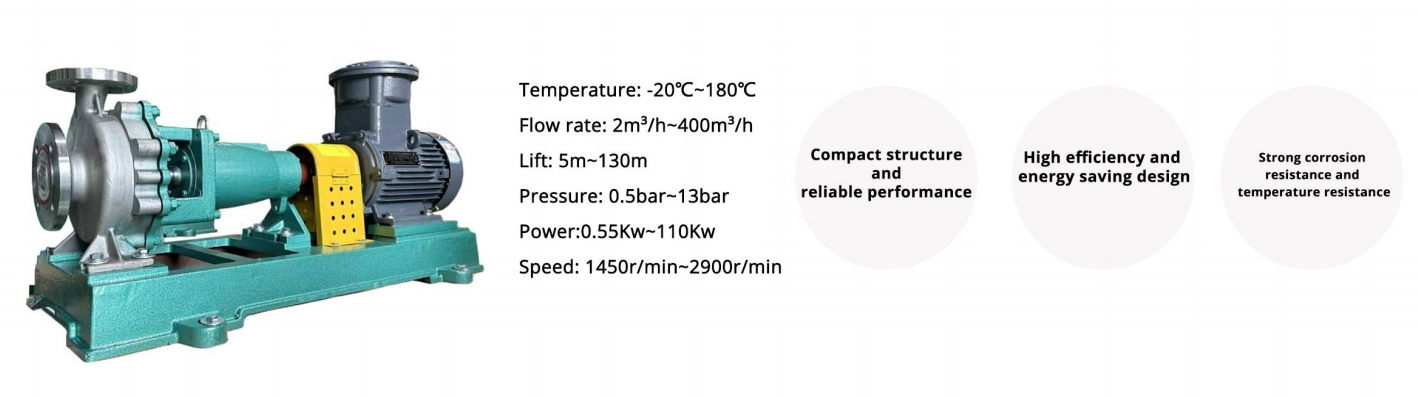

Flow Range :

5~400m³/hHead Range :

5~130mPower :

2.2~110KwTemperature :

-20-200℃Material :

Stainless steel (304, 316, 316L), duplex steelThe centrifugal sea water pump is available in 304, 316, 316L,2205, 2507 stainless steel, and super duplex stainless steel materials, suitable for conveying seawater, brine, and organic solvents of various concentrations. Typical applications include ballast and firefighting systems on ships, seawater aquaculture operations, seawater desalination plants, seawater pressurization and lifting systems, and various industrial processes requiring reliable seawater conveyance.

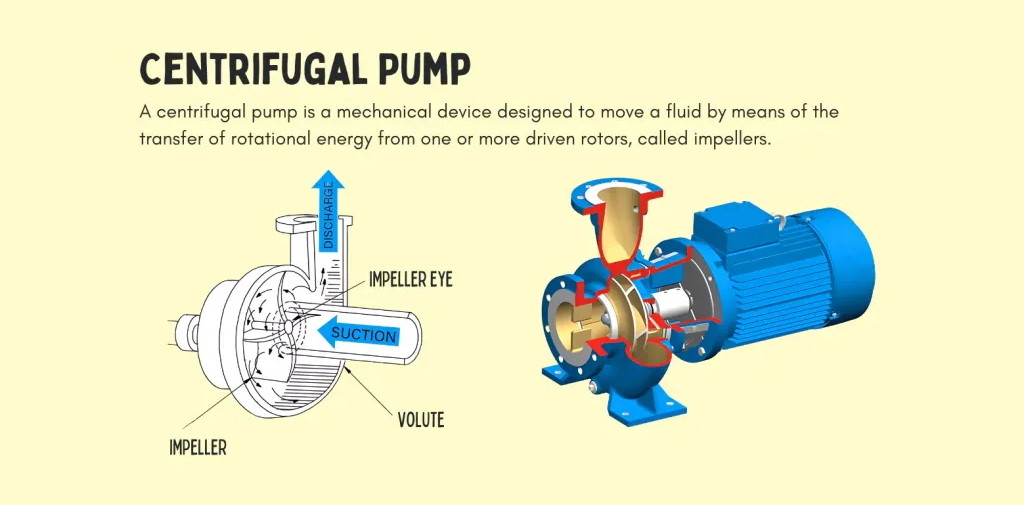

The centrifugal seawater pump operates by converting mechanical energy from a driver—such as an electric motor, engine, or turbine—into kinetic and pressure energy of the liquid. As the impeller, mounted on the pump shaft, rotates at high speed within the pump casing, seawater enters through the suction side and is accelerated outward along the impeller blades. The casing then guides the flow, transforming the liquid’s velocity into pressure before discharging it through the outlet. This design enables continuous, efficient transfer of large volumes of seawater under stable pressure.

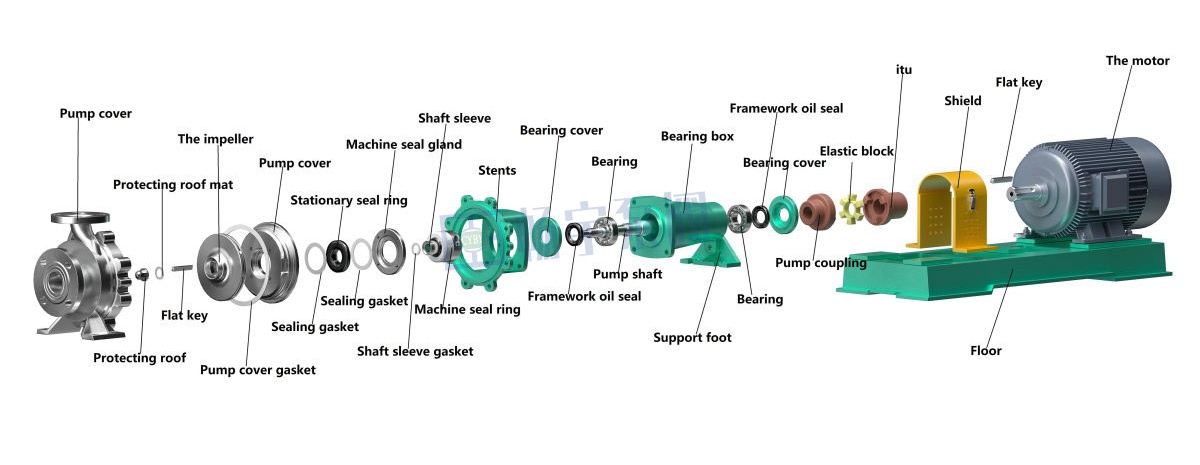

A centrifugal sea water pump is primarily composed of the impeller, pump casing, and drive unit.

The impeller is fixed to the pump shaft inside the casing, and when it rotates at high speed, seawater is drawn in through the eye of the impeller and expelled rapidly from the blade tips.

The casing channels the flow and converts the kinetic energy into pressure, while bearings within the housing support the pump shaft.

The drive unit supplies the rotational power required, commonly via an electric motor, though engines or turbines can also be used.

1.The adoption of a new hydraulic model has improved the efficiency compared to ordinary pumps.

2.It can effectively resist the cavitation phenomenon and reduce the damage to the pump body and impeller.

3.The horizontal structure design can basically meet all the pipeline installation requirements, and the installation methods are flexible and diverse.

4.It has good corrosion resistance and can adapt to the transportation of various corrosive media.

5.It is convenient for maintenance and the replacement of accessories is simple.

6.It has good mechanical seal performance, which can effectively prevent the leakage of media and extend the service life of the pump.

Suitable for conveying medium with low flow rate, high flowrate, high head, low NPSH, high/low temperature, easy crystalliza-tion, easy solidification, flammable, explosive, easy vaporization,volatile, highly toxic, corrosive, precious, clean particles.

| Industry / Field | Application of Centrifugal Sea Water Pump |

| Marine Industry | Ship ballast systems, marine firefighting, seawater cooling circulation |

| Aquaculture | Seawater supply for fish farms, water circulation in aquaculture tanks |

| Desalination Plants | Seawater intake, booster pumping for reverse osmosis systems |

| Power Plants | Cooling water circulation using seawater as the heat exchange medium |

| Chemical Industry | Transfer of brine, alkaline solutions, and other mildly corrosive seawater-based liquids |

| Port & Offshore Facilities | Seawater lifting, firefighting, and wash-down systems |

| Municipal Waterworks | Coastal water transfer projects and seawater lifting stations |

Changyu is a leading centrifugal sea water pump manufacturer and supplier with 22 years of expertise in pump design, production, and R&D. We offer a wide range of industrial centrifugal pumps tailored to diverse operating conditions, including seawater pumps, acid pumps, alkali pumps, and magnetic drive pumps. We have over 25 patented technologies and rich OEM/ODM experience, provide reliability, efficiency, and long service life. Certified to ISO 9001, CE, and ATEX standards, our products meet stringent quality and safety requirements for global markets. Whether you need a standard model or a fully customized design, our professional team is ready to provide the optimal solution. Contact us today to discuss your project requirements and receive a tailored proposal.

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

1.What is a Sea Water Pump?

A sea water pump is a pump specifically designed to move or circulate seawater in various applications, such as in desalination plants, cooling systems, and marine vessels. These pumps are made from materials that resist corrosion caused by saltwater, ensuring durability and reliable performance in harsh marine environments.

2.What does a seawater pump do?

A seawater lift pump is used to draw seawater from the ocean and lift it to a higher elevation for use in processes like cooling, desalination, or other industrial applications. It is essential for moving seawater into systems where it can be treated or used.

3.What is a salt water pump used for?

A salt water pump is used to move or circulate saltwater in applications such as marine systems, desalination plants, and aquariums. It is designed to handle the corrosive nature of saltwater, ensuring reliable performance in environments where seawater or brine is used.

4.What materials are used in seawater pumps?

Seawater pumps are typically made from materials that resist corrosion, such as stainless steel, bronze, titanium, and special plastics like polypropylene. These materials ensure durability and long-lasting performance in harsh saltwater environments.

5.What is the best material for a water pump?

The best material for a water pump depends on the application, but commonly used materials include stainless steel for corrosion resistance, cast iron for durability, and bronze for a balance of both. The choice depends on the specific water type and operating conditions.

What is Centrifugal Pump? Parts, Working Principle and Types

Types of Centrifugal Pumps and How to Select

How Does a Horizontal Centrifugal Pump Work

How Does a Centrifugal Pump Operate: Safety Operation Guide

Horizontal vs Vertical Centrifugal Pumps and How to Choose

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)