A centrifugal pump is a type of pump that utilizes the principle of centrifugal force to transport liquids. Its core function is to convert the rotational kinetic energy of an electric motor or engine into fluid energy, thereby generating flow and pressure. In this article, we will take an in-depth look at the key components of a centrifugal pump and its working principles. We will break down each component and explain its operational process to help you gain a clear and comprehensive understanding of this equipment.

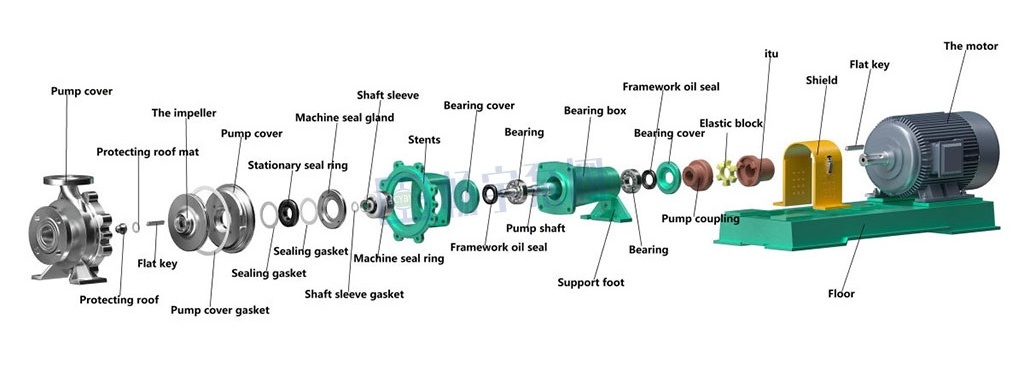

Although there are many types of centrifugal pumps with different applications, their basic core structures are similar. Understanding these key components will help you understand how centrifugal pumps work. We will provide a detailed introduction to the main core components of centrifugal pumps, including impellers, pump casings, and sealing systems.

It is one of the core components of a centrifugal pump, primarily responsible for transferring mechanical energy from the motor to the liquid, generating centrifugal force to impart kinetic and potential energy to the liquid.

Based on structural form, they are divided into open, semi-open, and closed types. Closed impellers have the highest efficiency and are the most widely used; open and semi-open impellers are suitable for conveying fluids containing solid particles or viscous fluids.

When the centrifugal pump starts, the pump shaft drives the impeller to rotate at high speed, forcing the liquid pre-filled between the blades to rotate. Under the influence of inertial centrifugal force, the liquid moves radially from the center to the outer periphery of the impeller.

The liquid gains energy as it flows through the impeller. When the liquid leaves the impeller and enters the pump casing, it decelerates due to the gradually expanding flow channels inside the casing, converting part of its kinetic energy into static pressure energy, and finally flows tangentially into the discharge pipeline.

The pump casing refers to the spiral-shaped flow channel with gradually increasing cross-sectional area from the impeller outlet to the inlet of the next stage impeller or to the pump outlet pipe. The flow channel gradually widens, converting the fluid's kinetic energy into static pressure energy, which is then discharged through the pipe.

Collecting high-speed fluid flowing out from the impeller outlet;

Effectively converting the fluid's kinetic energy into pressure energy;

Smoothly guiding the pressurized fluid to the pump's discharge piping;

Withstanding the fluid pressure inside the pump.

Snail-shell type pump casing: The most common type, with a spiral-shaped flow channel cross-section and a simple structure.

Guide vane pump casing: Features fixed guide vanes mounted around the impeller's periphery. The guide vanes convert the fluid's kinetic energy into pressure energy and direct the fluid toward the outlet. Commonly used in multistage pumps or high-pressure pumps.

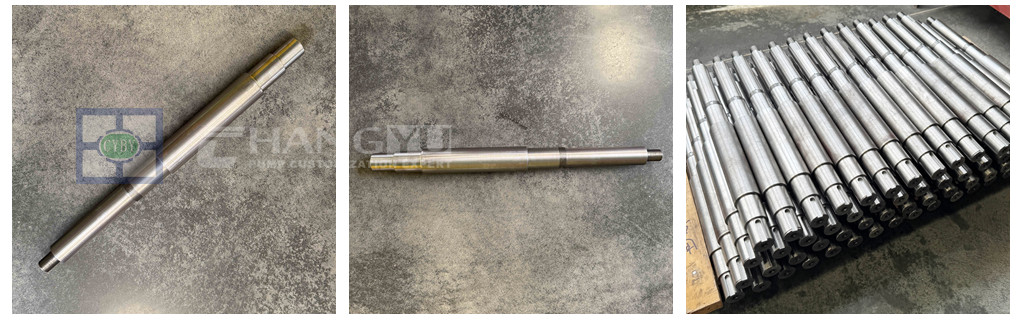

Its primary function is to transmit power and support the impeller to maintain normal operation at its working position. Since it must perform additional energy conversion functions, its material must possess sufficient strength, stiffness, and wear resistance. It is typically made of high-strength alloy steel.

The impeller and shaft are connected via a key. Since this connection method can only transmit torque and cannot fix the axial position of the impeller, a shaft sleeve and locking nut are also used in the pump to secure the axial position of the impeller.

The shaft sleeve protects the pump shaft, transforming the friction between the packing and the shaft into friction between the packing and the shaft sleeve. Therefore, the shaft sleeve is a wear-prone component in centrifugal pumps.

The surface of the shaft sleeve can typically be treated using methods such as carburizing, nitriding, chrome plating, or coating. The surface roughness requirement generally needs to reach Ra3.2 μm to Ra0.8 μm. This reduces the friction coefficient and extends the service life.

A skeleton oil seal is one of the most common and widely used types of seals for rotating shafts, commonly known as oil seals. Its primary function is to seal lubricating oil (or grease) within mechanical equipment while preventing external contaminants such as dust and mud from entering the system.

The working principle of centrifugal pump involves the high-speed rotation of the impeller, which imparts kinetic energy to the liquid under the influence of centrifugal force and converts it into pressure energy, thereby achieving fluid conveyance. Before startup, the pump housing and suction piping must be completely filled with the medium to prevent cavitation.

During operation, the rotating impeller causes the liquid to move at high speed and be flung toward the outer edge, while a low-pressure zone forms at the center of the impeller, continuously drawing in liquid and conveying it to the outlet. Through continuous cyclic operation, a steady and continuous conveying process is achieved.

Through the above content, we believe you now have a good understanding of centrifugal pump parts and how they work. If you have any further questions or technical issues regarding this equipment, please feel free to contact the Changyu technical team at any time. We will respond quickly within 24 hours and address your concerns.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)