In industrial and civil applications, centrifugal pumps are widely used in water treatment, heating and cooling, irrigation, drainage, and other scenarios. Understanding a centrifugal pump's efficiency not only helps evaluate its operational status but also guides energy conservation, reduces maintenance costs, extends equipment lifespan, and prevents excessive wear. Today, we'll explain how to calculate centrifugal pump efficiency—covering principles, calculation methods, and practical significance.

Pump efficiency fundamentally measures a machine's ability to convert input energy into useful output energy. If 1 unit of input energy yields only 0.5 units of output, the efficiency is 50%. While seemingly straightforward, real-world engineering involves diverse energy forms and units—mechanical, electrical, hydraulic, etc. Appropriate conversion factors enable unit comparison and standardized efficiency calculations.

For centrifugal pumps (using water as the medium), overall efficiency is defined as the ratio of output power to input shaft power:

Ef = Pw / Ps

Where:

Ef —— Overall efficiency;

Pw —— Output power (hydraulic water power);

Ps —— Input shaft power (brake horsepower, BHP).

Under commonly used US units, the water power formula is:

Pw = (Q × H) / 3960

Q: Flow rate (GPM, gallons per minute)

H: Head (ft)

3960: Constant for converting GPM × ft to horsepower (BHP)

Example: For a pump operating at 30 ft head and 100 GPM flow rate, if BHP = 1, then:

Pw = (100 × 30) / 3960 ≈ 0.757 BHP, yielding an efficiency of approximately 75.7%.

The overall efficiency of a centrifugal pump is actually the product of three component efficiencies:

Mechanical efficiency (ηₘ): Friction losses from bearings, stuffing boxes, or mechanical seals.

Volumetric efficiency (ηᵥ): Leakage losses due to wear rings, balance holes, and blade clearances.

Hydraulic efficiency (ηₕ): Energy losses caused by friction within the impeller and pump casing.

Therefore:

η_total = ηₘ × ηᵥ × ηₕ

Among these factors, hydraulic efficiency is often the most significant contributor to centrifugal pump efficiency.

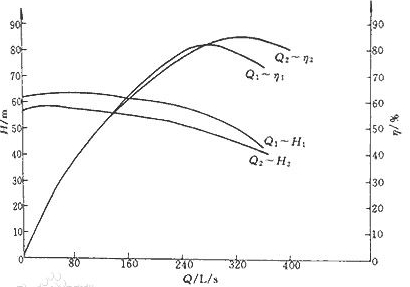

During the design phase, the primary adjustable parameters for centrifugal pumps are the impeller and volute (or diffuser, guide vanes), analogous to the rotor and stator in electric motors. The relationship between impeller parameters and rotational speed/diameter is fundamental:

Head is proportional to the square of rotational speed: Doubling speed quadruples head; minor diameter adjustments follow similar patterns.

Flow rate is proportional to speed or diameter: doubling either parameter doubles the flow rate.

Additionally, the impeller's cross-sectional area, flow channel width and depth, inlet dimensions, and blade shape directly impact fluid flow efficiency, thereby influencing overall performance. Historically, pump design relied heavily on manual trials and iterative prototype testing. Today, engineers can leverage empirical formulas and parameters like specific speed to rapidly identify optimal design starting points.

Actual Flow Rate Q: Obtain true GPM using a flow meter;

Measure Head H: Derive from pressure differential conversion, units in ft;

Record Shaft Power Ps: Obtain BHP (or kW) using power measurement equipment;

Calculate water power Pw: Input Q and H from above;

Derive efficiency: Ef = Pw ÷ Ps;

Further analyze efficiency components: If efficiency is low, use thermal imaging, leak testing, vibration analysis, etc., to identify which component is causing the efficiency drop (mechanical, volumetric, hydraulic).

Centrifugal pump efficiency serves as a critical metric for evaluating operational performance, energy conservation levels, and operating costs. Overall efficiency comprises three components: hydraulic, mechanical, and volumetric losses. Understanding the design principles of impellers and volutes—such as the specific speed curve—provides a solid foundation for both design and diagnostic processes. By measuring actual flow rate, head, and shaft power, formulas like Pw = (Q × H) / 3960 can quantify pump efficiency. If efficiency is low, identify and improve corresponding components to enhance overall performance.

Should you encounter any questions during pump selection, efficiency measurement, optimization, or diagnostics, our expert team stands ready to assist. With extensive experience and specialized equipment, we are committed to delivering efficient, safe, and reliable pump solutions.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)