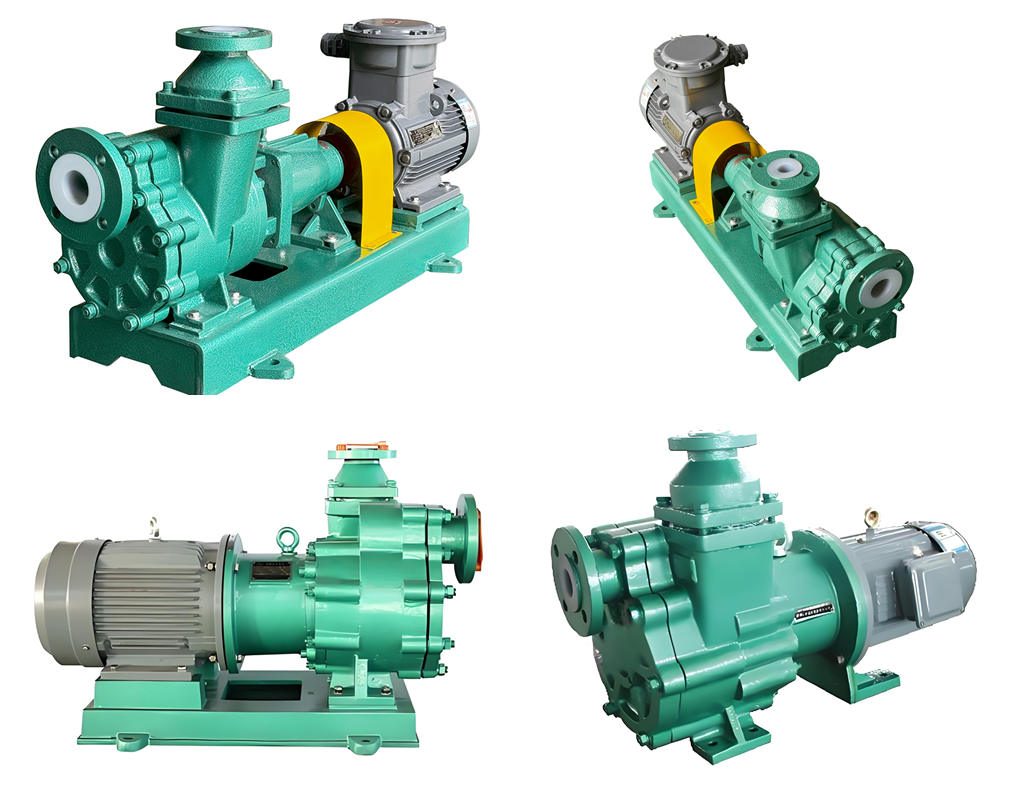

The FZB Fluorine-lined Self-Priming Centrifugal Pump integrates the dual advantages of magnetic drive and self-priming centrifugal technology. It combines the reliable, fully sealed, and leak-free characteristics of a magnetic pump with the powerful self-priming capability of a self-priming centrifugal pump, achieving a self-priming height of up to 5 meters. It is specifically designed for conveying highly corrosive media where the suction inlet is below the liquid level, enabling safe and efficient transportation of various acids, alkalis, organic solvents, and other harsh media. It is an ideal solution to replace traditional submersible pumps.

Flow Range :

2.5m³/h-100m³/hHead Range :

15m-50mPower :

CustomTemperature :

-20°C-150°CMaterial :

Lining F46, PFAThe FZB Fluorine-lined Self-Priming Centrifugal Pump is particularly suitable for applications in industries such as chemicals, pharmaceuticals, electroplating, and environmental protection, including container drainage, low-level tank conveying, and sensitive areas where leakage must be prevented. Featuring an innovative structural design, it eliminates the need for complex mechanical seals and priming steps, thereby reducing maintenance costs and operational risks. With its corrosion-resistant lining material and efficient self-priming performance, it offers superior sealing performance and eliminates the risk of leakage, providing a more flexible and safer process pumping solution that enhances the reliability and environmental friendliness of production systems.

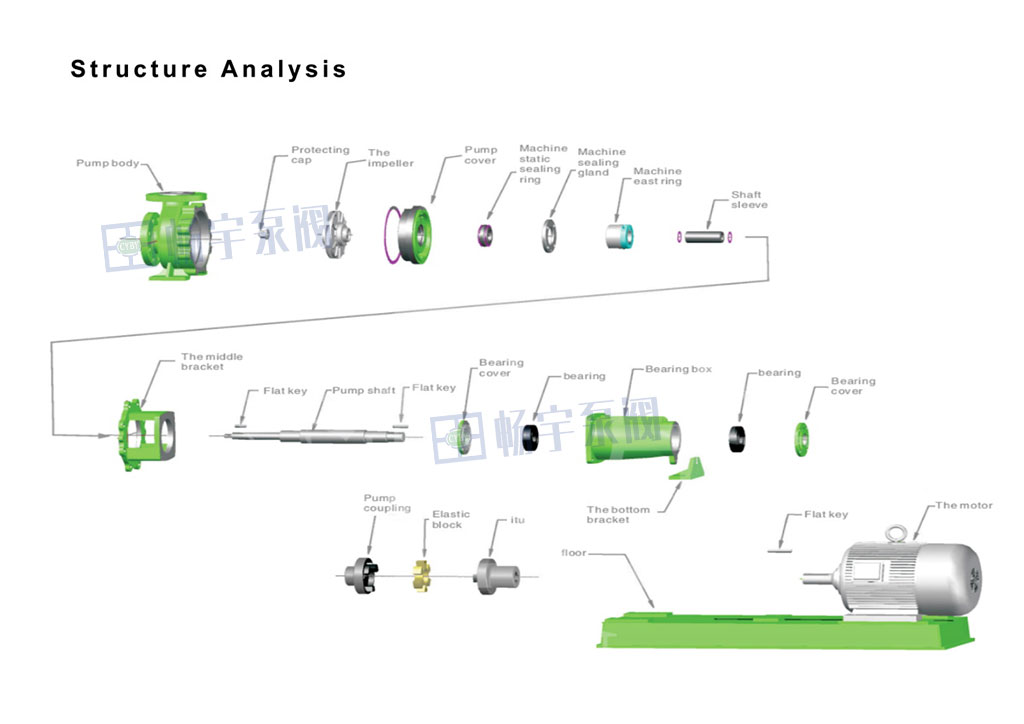

The FZB-type fluoroplastic-lined self-priming centrifugal pump primarily consists of core components such as the fluoroplastic-lined pump body, impeller, self-priming device, shaft seal system, and drive unit. If you have specific operational conditions or selection requirements, we can provide further technical support and customized product services.

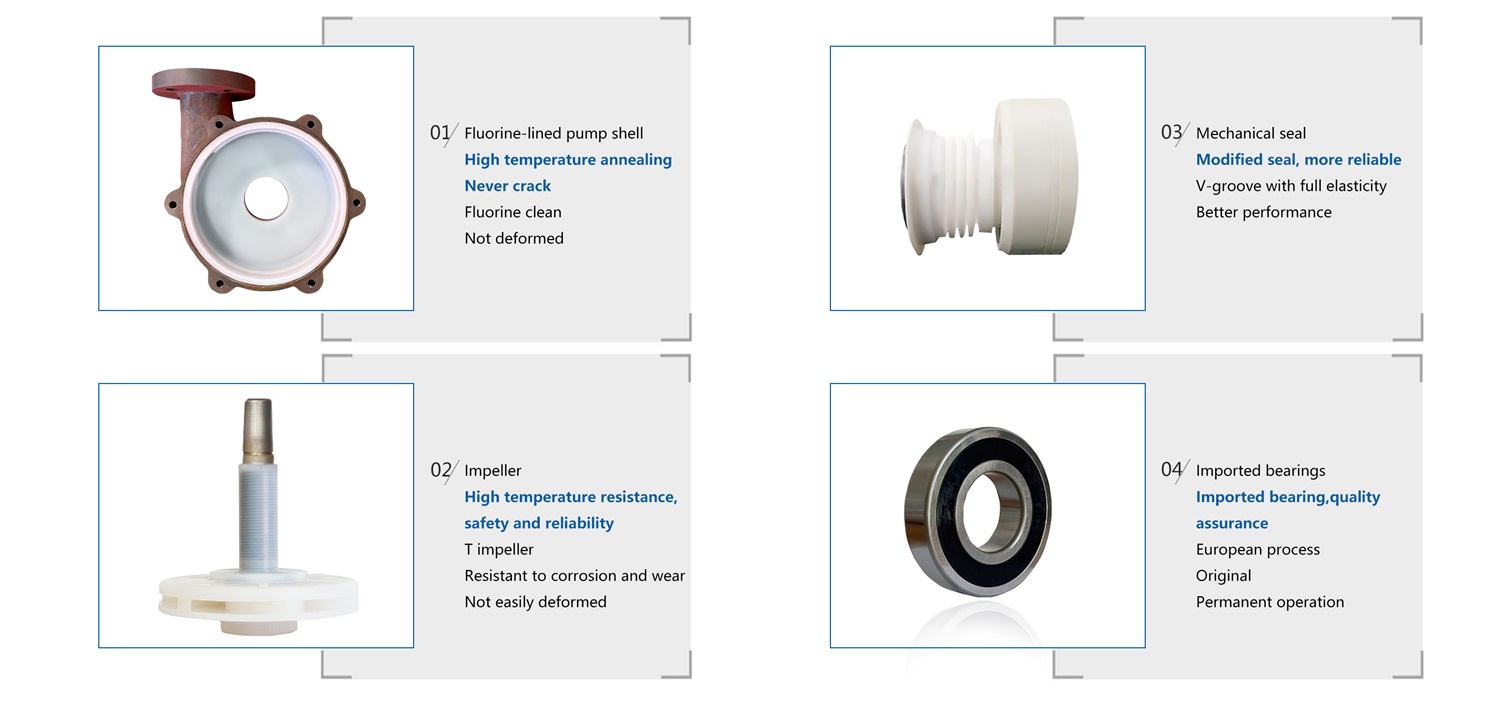

Fluoroplastic-lined pump body: Constructed with a high-performance fluoroplastic lining, it offers excellent resistance to strong corrosive media and is suitable for various chemical liquids such as acids, alkalis, and solvents.

Impeller: Made of fluoroplastic or composite materials, it features superior corrosion resistance and hydraulic performance, enabling efficient medium transportation.

Self-priming device: Integrated self-priming structure allows the pump to rapidly self-prime within the suction head range (e.g., 5 meters) without requiring priming liquid.

Sealing system: Optional mechanical seals or leak-free magnetic drive systems are available to effectively prevent the leakage of hazardous media and enhance operational safety.

Drive unit: Equipped with high-efficiency motors as standard, supporting various power ratings and explosion-proof grades to meet the needs of different industrial environments.

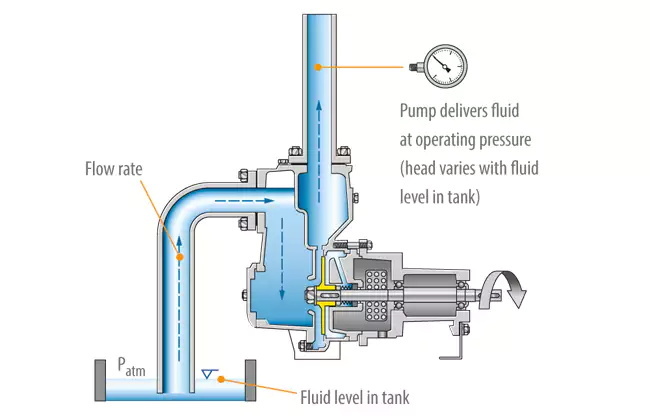

The FZB-type fluoroplastic-lined self-priming centrifugal pump operates by combining the principle of centrifugal force with a self-priming structure:

After startup, the impeller inside the pump cavity rotates at high speed, creating a vacuum at the inlet, thereby drawing liquid below the pump inlet into the pump; the liquid follows the impeller in a centrifugal motion, gradually converting kinetic energy into pressure, and is ultimately discharged through the outlet. This pump features a highly corrosion-resistant fluoroplastic lining and a unique self-priming structure, enabling it to achieve a self-priming height of 5 meters without the need for priming liquid, ensuring leak-free operation throughout the process and safe transportation of various corrosive media.

The FZB-type fluoroplastic-lined self-priming centrifugal pump features the following core characteristics:

Strong medium adaptability

Specifically designed for harsh operating conditions in the chemical industry where the liquid level is below the pump inlet, it safely transports neutral or highly corrosive liquids, withstands temperatures from low to high (up to 150°C), and handles slurry media with solid particle content below 5%, achieving efficient and reliable transportation of complex fluids.

Excellent corrosion resistance

Utilizing advanced fluoroplastic lining technology, it can withstand various strong acids, strong alkalis, and organic solvents that stainless steel cannot handle. It can replace high-end pump models made from expensive materials such as titanium alloy, Hastelloy, and Monel alloy, offering both safety and cost-effectiveness.

High-efficiency self-priming and leak-free operation

The pump has excellent self-priming capability, with a self-priming height of up to 5 meters, eliminating the need for priming liquid before startup and simplifying operation. Additionally, it employs magnetic drive or seal-less structures to completely eliminate leakage risks, making it particularly suitable for workshops and laboratories with strict environmental safety requirements.

Low-maintenance design

The pump body has a compact structure, and its modular design facilitates disassembly and maintenance. The inner lining made of fluorinated materials is resistant to adhesion and wear, extending the service life, reducing downtime, and lowering overall operational costs.

The FZB-type fluoroplastic-lined self-priming centrifugal pump is widely used in the following industries and applications:

Chemical and New Materials Industry: Suitable for the transportation of corrosive media such as strong acids, strong alkalis, organic solvents, and corrosive substances in new material synthesis processes. It is particularly suitable for feedstock loading into reactors, intermediate transfer, and the transportation of high-purity chemicals, meeting the stringent requirements for corrosion resistance and zero leakage under harsh operating conditions.

Environmental Protection and New Energy Sector: Widely used in wastewater treatment, electroplating solution circulation, collection of waste liquid from acid washing lines, transportation of electrolyte in the preparation of new energy battery materials, and flue gas desulfurization and deacidification processes, capable of withstanding corrosive and complex fluids containing trace particles.

Biopharmaceutical and Food Engineering: Complies with GMP requirements for the transportation of pharmaceutical solutions, culture media, dilute acids and alkalis, and food-grade solvents. It can achieve clean self-priming and prevent contamination, making it suitable for tanks with liquid levels below the pump inlet, fermentation tank feeding, and CIP systems.

Metallurgy, Electroplating, and Surface Treatment: Used in mining and metallurgy for leaching solutions and extractant transportation, in the electroplating industry for plating solutions and acid copper solution circulation, and in the dyeing industry for dye and additive addition. Effectively handles harsh environments with high temperatures, corrosion, and particulate impurities.

Changyu Pump is a professional manufacturer specializing in the research, development, and production of centrifugal pumps. With 22 years of industry experience and technical expertise, we provide customized solutions for corrosion-resistant, self-priming, high-efficiency, safe, and reliable FZB-type fluoroplastic-lined self-priming centrifugal pumps for customers across various industries. Our team will provide you with professional, cost-effective, and efficient pumping solutions based on the information you provide. For further technical consultation or to request product information, please feel free to contact us at any time!

To ensure precise matching of pump type and configuration, please provide the following information:

What is Centrifugal Pump? Parts, Working Principle and Types

Types of Centrifugal Pumps and How to Select

How Does a Horizontal Centrifugal Pump Work

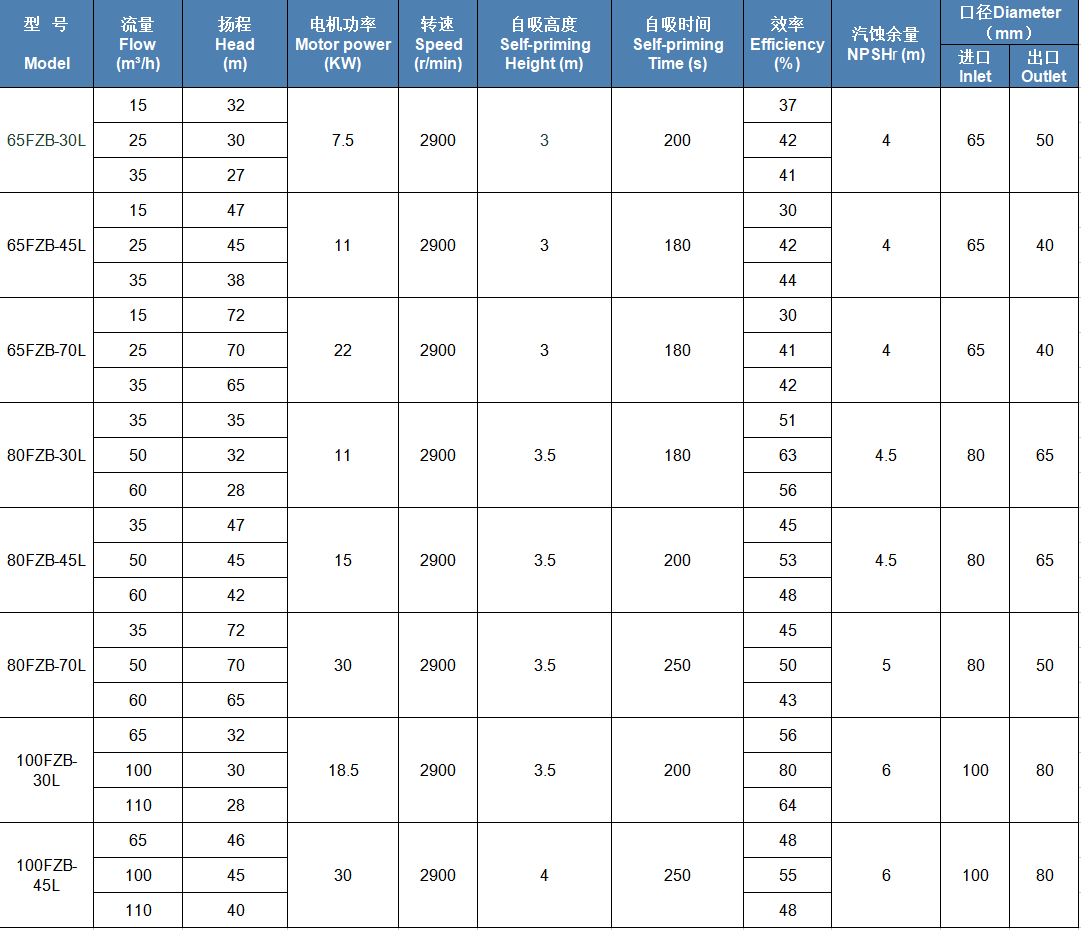

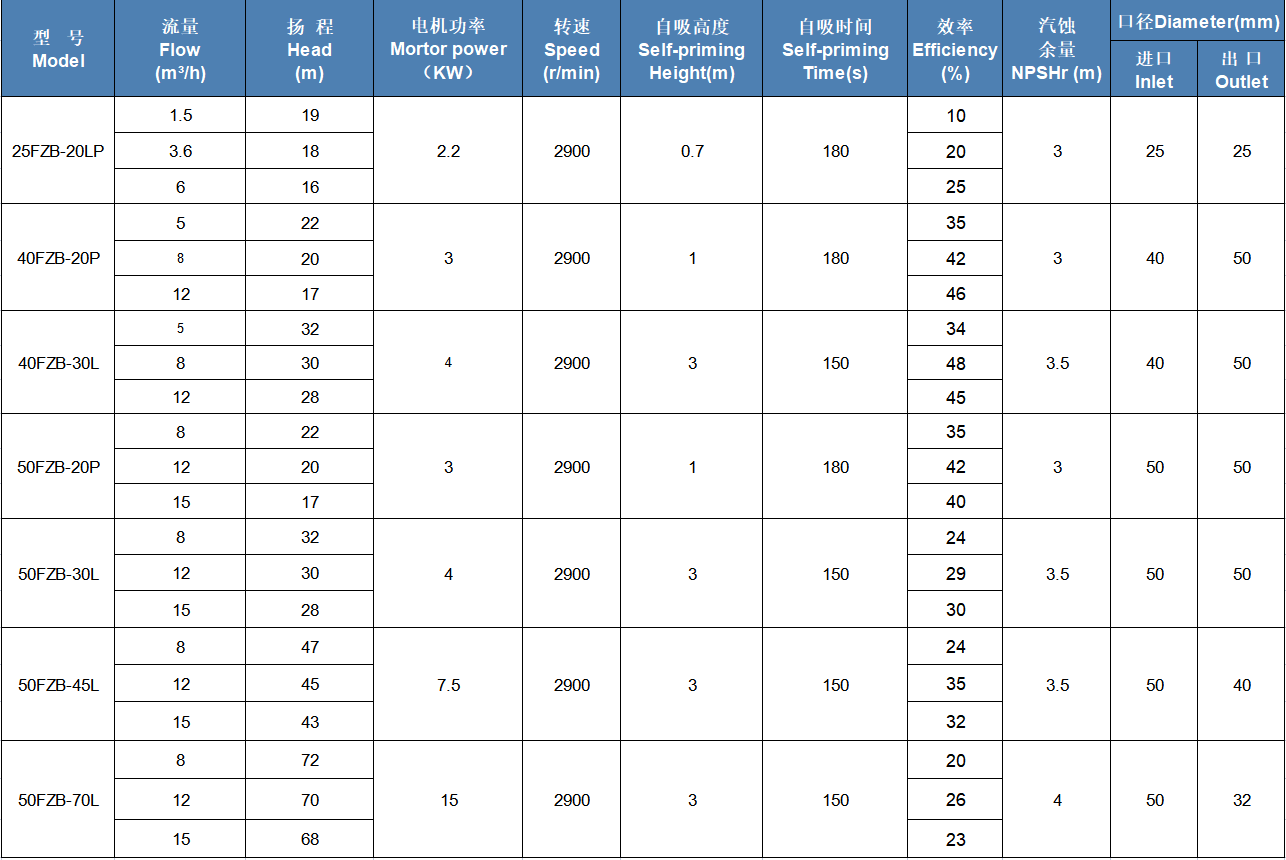

For more detailed performance parameters or selection support, please contact our technical team.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)