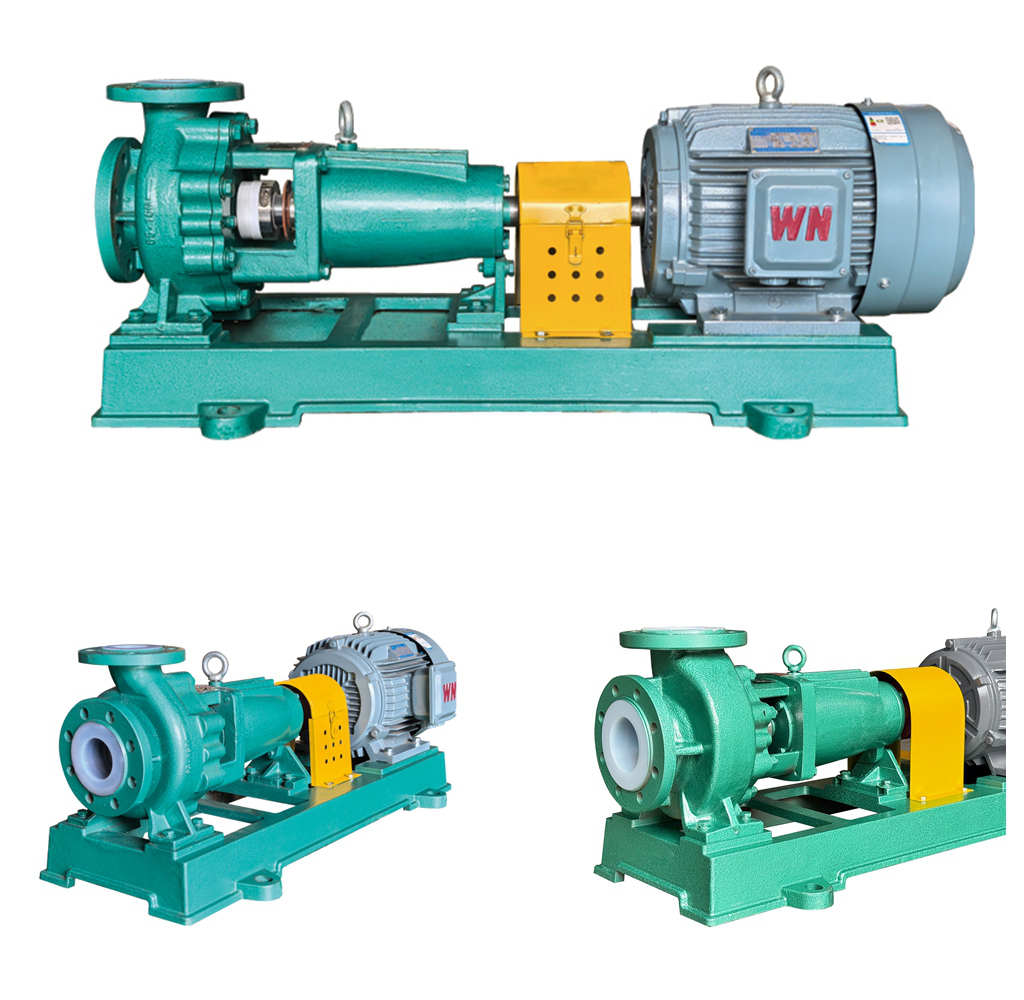

The CYF Series Hydrochloric Acid Transfer Centrifugal Pump is specifically designed for corrosive environments. It is widely used in chemical, petroleum, pharmaceutical, dyeing, metallurgical, papermaking, and food industries, serving as an ideal solution for the safe and efficient transfer of corrosive media.

Flow Range :

3~2600m³/hHead Range :

5~130mPower :

0.55~110KwTemperature :

-20-180℃Material :

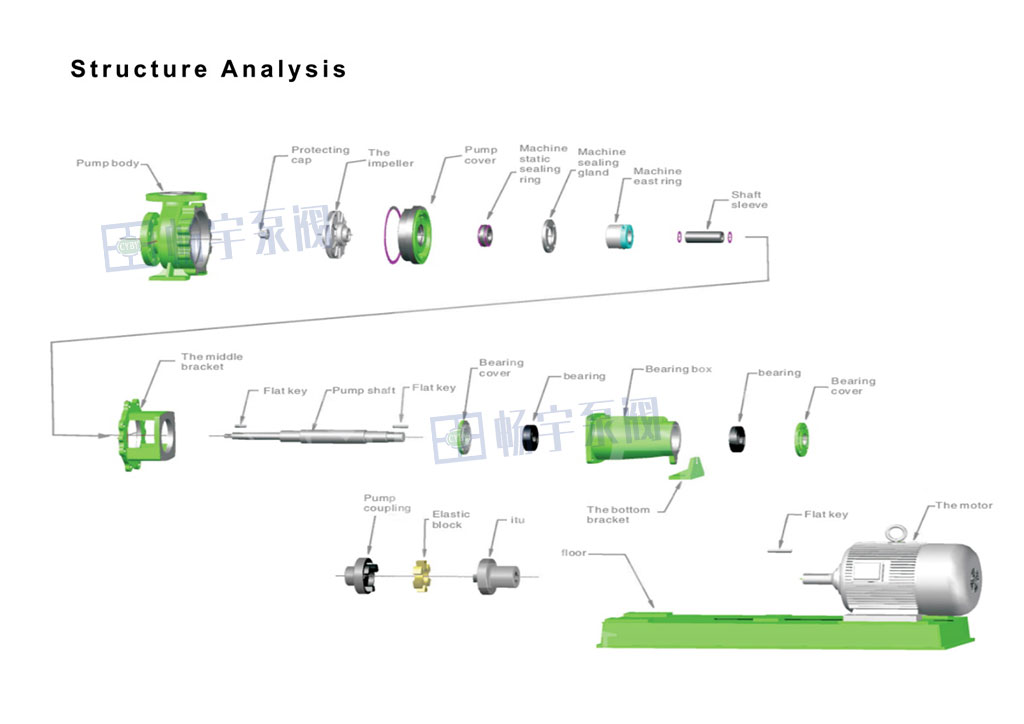

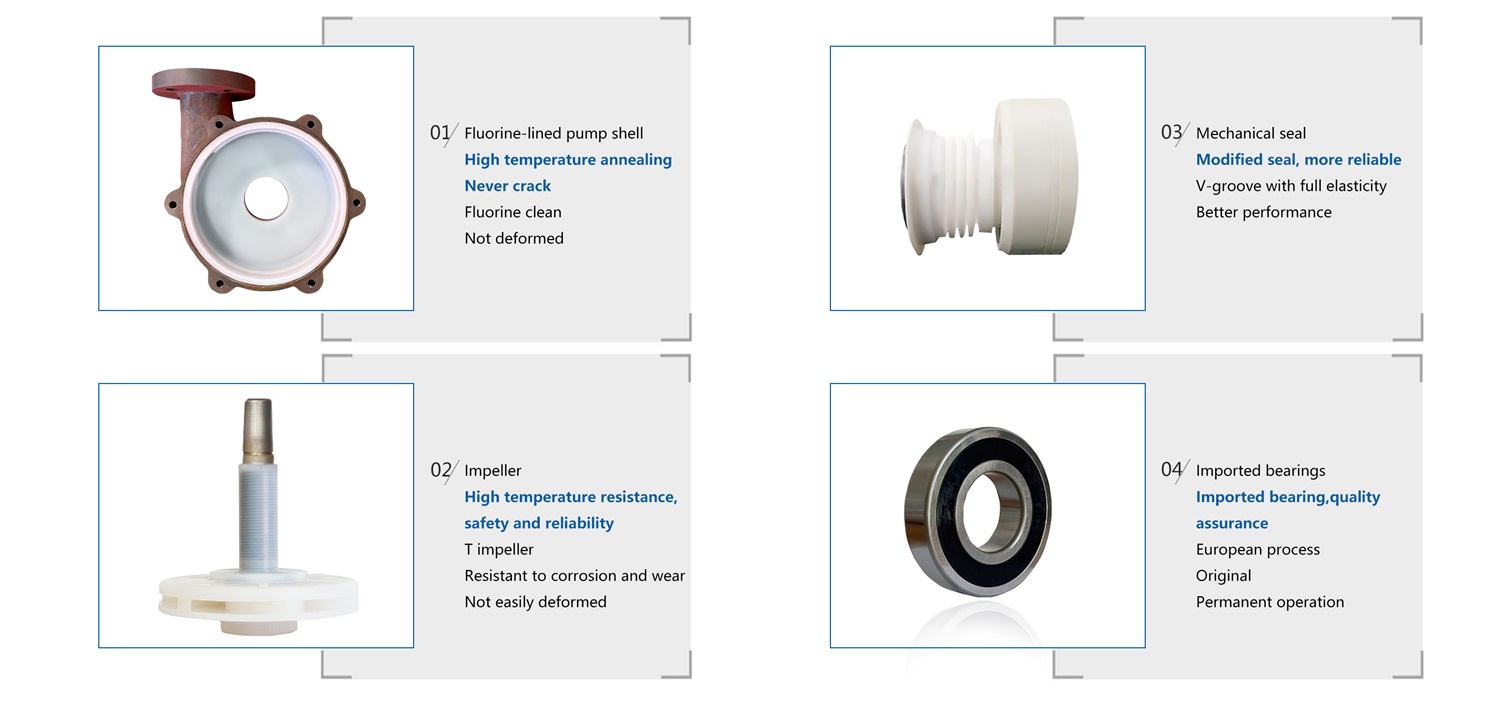

Steel-lined FEP, PFA, PTEFThe CYF series hydrochloric acid centrifugal pumps (referred to as the hydrochloric acid pump) are strictly designed in compliance with ISO international standards. Featuring integrated non-metallic materials and fluid structures, they are suitable for long-term transportation of acids, alkalis, hydrogen peroxide, and other highly corrosive media (free of solid particles) at any concentration under operating conditions ranging from -85°C to 200°C. These pumps exhibit strong corrosion resistance, anti-aging properties, and chemical stability, while their non-toxic, non-degradable materials ensure the purity of the transported media.

This pump model features high energy efficiency, a wide flow and head range, compact structure, and easy maintenance. Its excellent overall sealing performance completely eliminates the common leakage issues found in traditional pumps and valves.

The chemical centrifugal pump for hydrochloric acid transfer is a high-performance corrosion-resistant pump made of plastic alloy, developed through specialized processes and innovative design. Featuring a compact structure, smooth operation, easy maintenance, and energy efficiency, it is the ideal equipment for transferring highly corrosive media. This pump is specifically designed for conveying various corrosive liquids, primarily including:

⚠️ Precautions: Strictly prohibited from conveying media prone to rapid crystallization or containing large amounts of hard particles. If conveying materials with a small amount of particles is necessary, a wear-resistant mechanical seal must be selected and the operating conditions must be specified in advance.

With over 20 years of specialized expertise as a corrosion-resistant pump manufacturer and supplier, Changyu remains committed to delivering high-performance, highly reliable fluid transfer solutions to global customers. Focused on corrosion resistance, our specialized chemical centrifugal pumps for hydrochloric acid transfer integrate advanced material technology, precision manufacturing, and innovative design. Widely used in chemical, pharmaceutical, electroplating, metallurgical, environmental protection, and new energy industries, they are the ideal choice for handling various highly corrosive media. We provide pump model selection, material optimization, and custom design services tailored to your specific medium characteristics, temperature ranges, and operational requirements.

For further details on compatible models, technical specifications, or customization needs, please contact our professional technical team. We offer personalized selection support and rapid quotation services.

What is Centrifugal Pump? Parts, Working Principle and Types

Types of Centrifugal Pumps and How to Select

How Does a Horizontal Centrifugal Pump Work

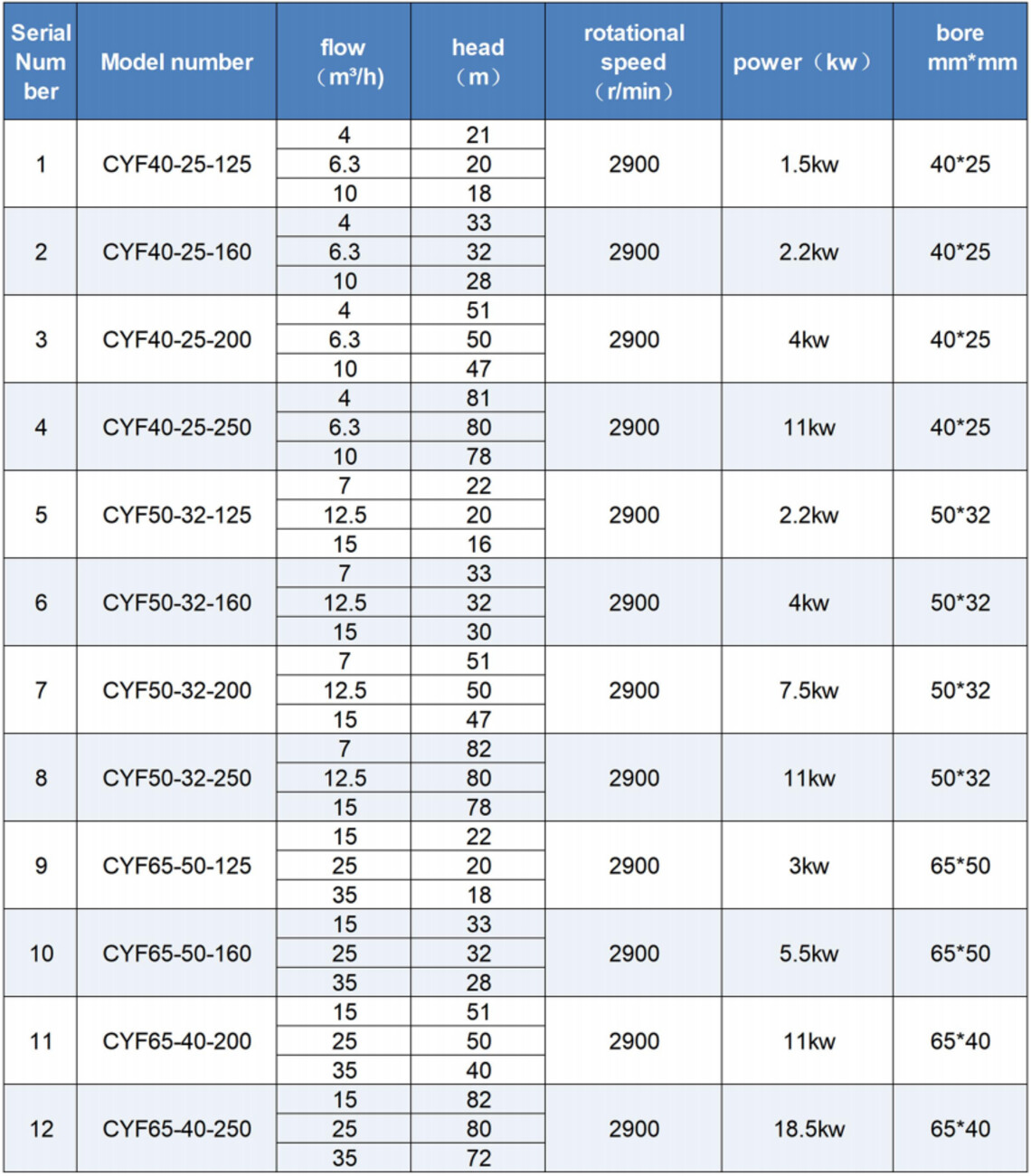

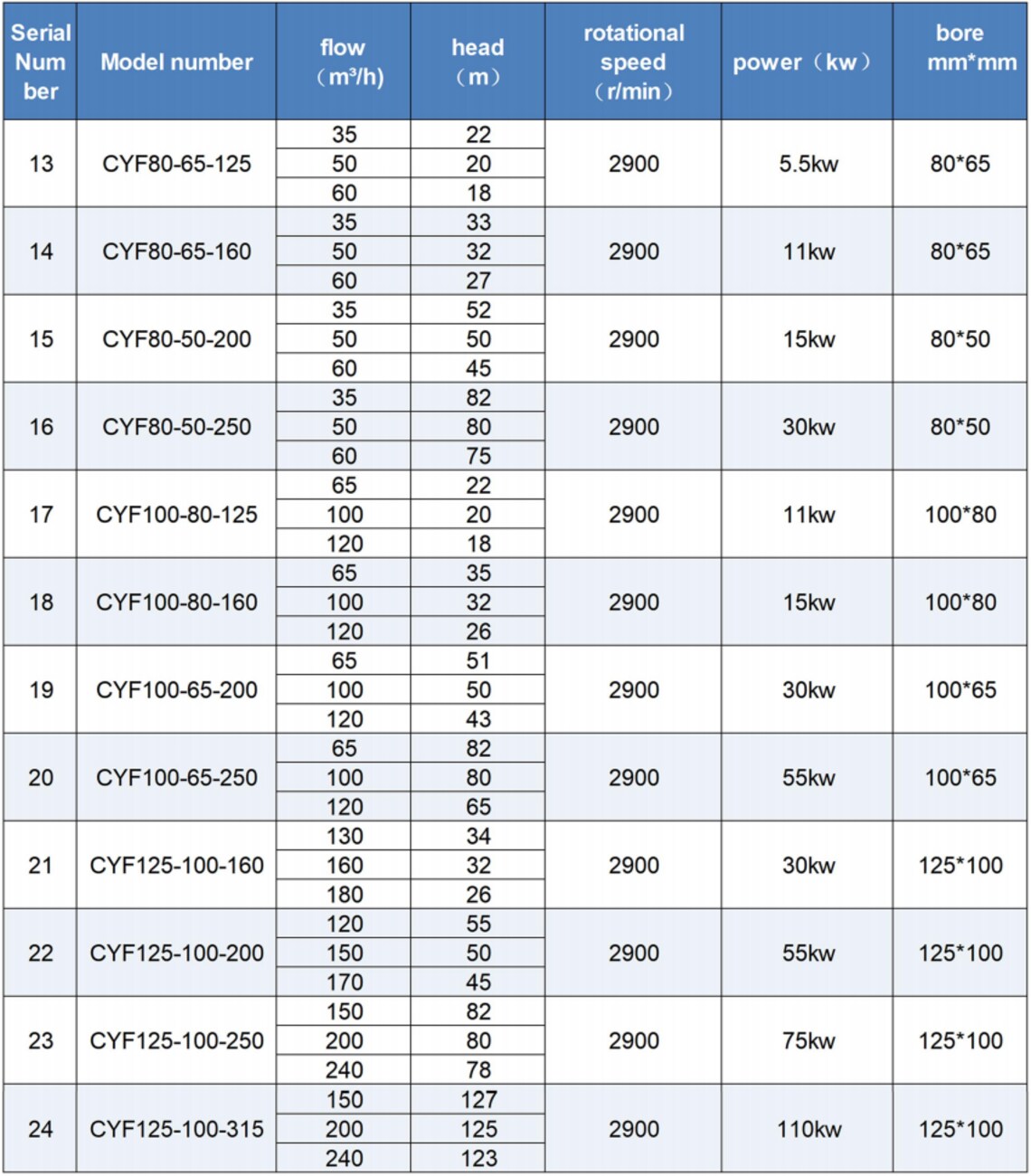

Specifications

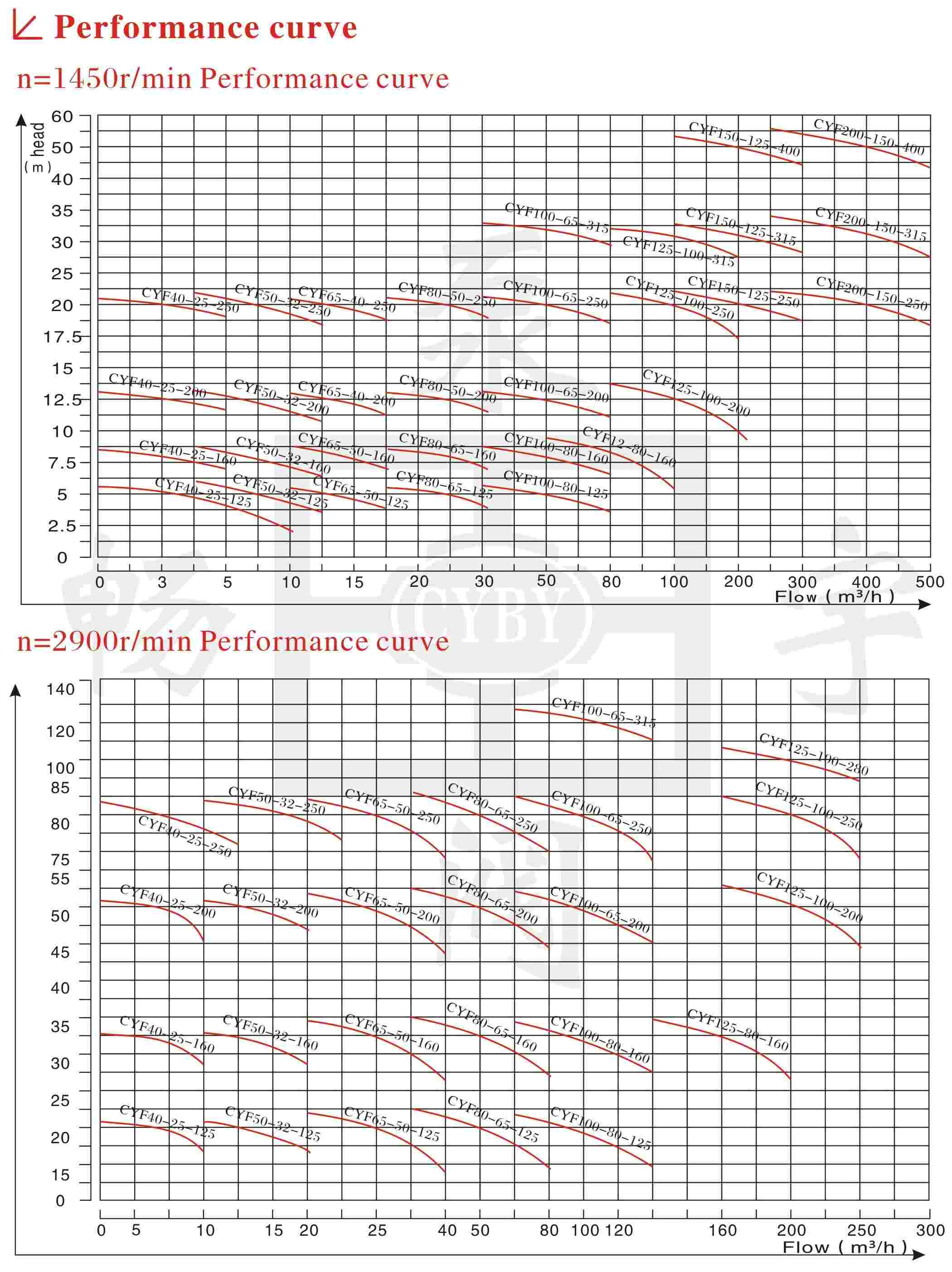

2: Performance curve

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)