Sep 01, 2025

In industrial fluid transfer systems, horizontal centrifugal pumps and vertical centrifugal pumps are the two most common pump types. Simply put, horizontal centrifugal pumps feature a horizontally mounted shaft, a simple structure, and are widely used in water supply, air conditioning circulation, and industrial pressurization applications. Vertical centrifugal pumps, with their vertically oriented shafts, are commonly used for pumping from low-level liquid reservoirs (such as underground tanks or drainage pits) or in applications with limited installation space. Although both belong to the centrifugal pump category and share similar hydraulic performance, they exhibit significant differences in structure, installation, maintenance, and application scenarios. Below, we provide a detailed comparison across multiple dimensions to help you make a more suitable choice.

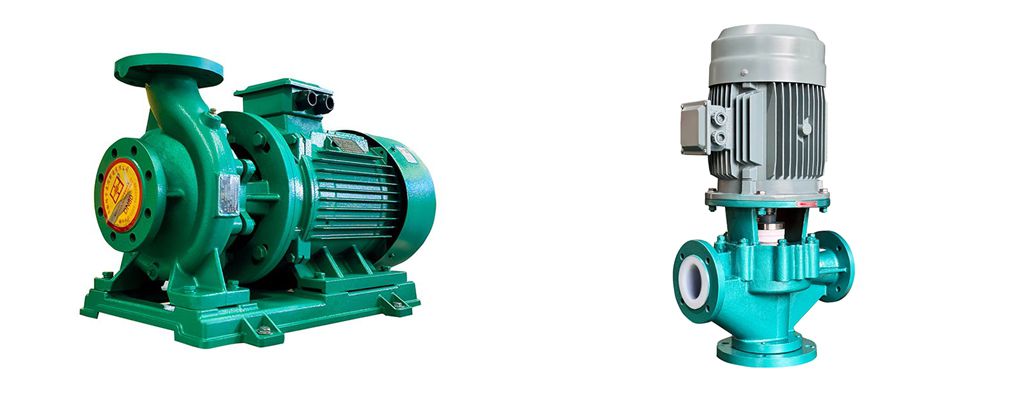

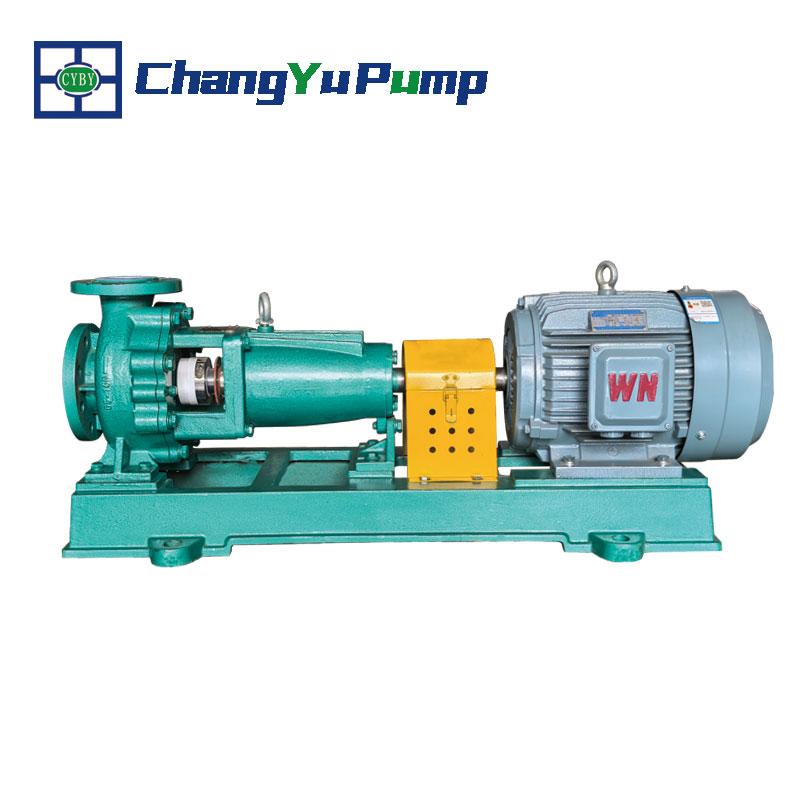

Structural Comparison

Horizontal centrifugal pumps feature a horizontally arranged shaft, with the motor typically directly coupled to the pump body via a coupling. This compact design facilitates installation and commissioning. Visually, their base is usually monolithic and requires anchoring to a foundation platform.

Vertical centrifugal pumps employ a vertical shaft design, with the motor positioned above the pump body, allowing the pump to operate submerged in liquid. Their slender structure generally eliminates the need for additional foundation supports, allowing direct installation atop tanks or reservoirs to save floor space.

Working Principle

Despite differing installation methods, both share identical core operating principles. Both horizontal and vertical centrifugal pumps rely on the centrifugal force generated by a high-speed rotating impeller to expel fluid, creating a vacuum that draws in liquid for continuous conveyance.

Advantages and Application Scenarios Comparison

Horizontal Centrifugal Pump Advantages and Applications

Advantages:

Easy Maintenance: Simple structure requires no pipeline disassembly or motor lifting during repairs, facilitating inspection and component replacement.

Stable Operation: Typically suited for steady-state conditions. Installation must ensure level positioning, resulting in low vibration and reliable operation.

Applications: Horizontal centrifugal pumps are the preferred choice for most conventional applications, commonly used in factory water supply, cooling systems, industrial cleaning, and similar scenarios.

Advantages and Applications of Vertical Centrifugal Pumps

Advantages:

Suitable for Backflow Conditions: Particularly effective for suctioning media from underground tanks or low-level liquid reservoirs, addressing the insufficient suction lift limitations of many horizontal pumps (non-self-priming types).

Space-Saving: Vertical design minimizes footprint and eliminates the need for specialized foundations, making it ideal for installations with limited space.

No Self-Priming Issues: Effectively handles low-level suction demands that horizontal pumps struggle to manage.

Applications:

Vertical pumps are primarily used for lifting and conveying liquids from lower elevations, such as deep well water extraction, tunnel drainage, sewage treatment, and medium transfer within chemical containers.

How to Choose Between Horizontal and Vertical Centrifugal Pumps?

The selection between horizontal and vertical pumps primarily depends on actual operational requirements:

Installation Conditions:

If ample space is available for foundation construction, prioritize the easier-to-maintain horizontal pump. For confined spaces or direct tank mounting, select a vertical pump.

Liquid Level Position:

For pumping from underground tanks or low-level media, choose a vertical centrifugal pump. Standard horizontal centrifugal pumps have poor self-priming capability and cannot meet such requirements.

Maintenance Costs

Horizontal pumps feature simpler maintenance with lower associated costs. Vertical pumps, however, require more complex servicing—including full lifting for repairs—and necessitate regular inspection and replacement of their submerged sliding bearings. Failure to do so may increase shaft runout, leading to mechanical failures. Installation demands absolute vertical alignment and high precision.

In Summary

In summary, horizontal and vertical centrifugal pumps are complementary products designed for distinct application scenarios. Horizontal pumps excel in simplicity and ease of maintenance, making them ideal for most standard applications. Vertical pumps, however, are unmatched in low-level pumping and space-saving designs, proving indispensable in specific operating conditions.

Should you encounter any technical issues regarding pump selection, application, or maintenance, please feel free to contact our professional technical team at any time. We will provide detailed explanations and reliable solutions.

Read More