May 22, 2025

Introduction

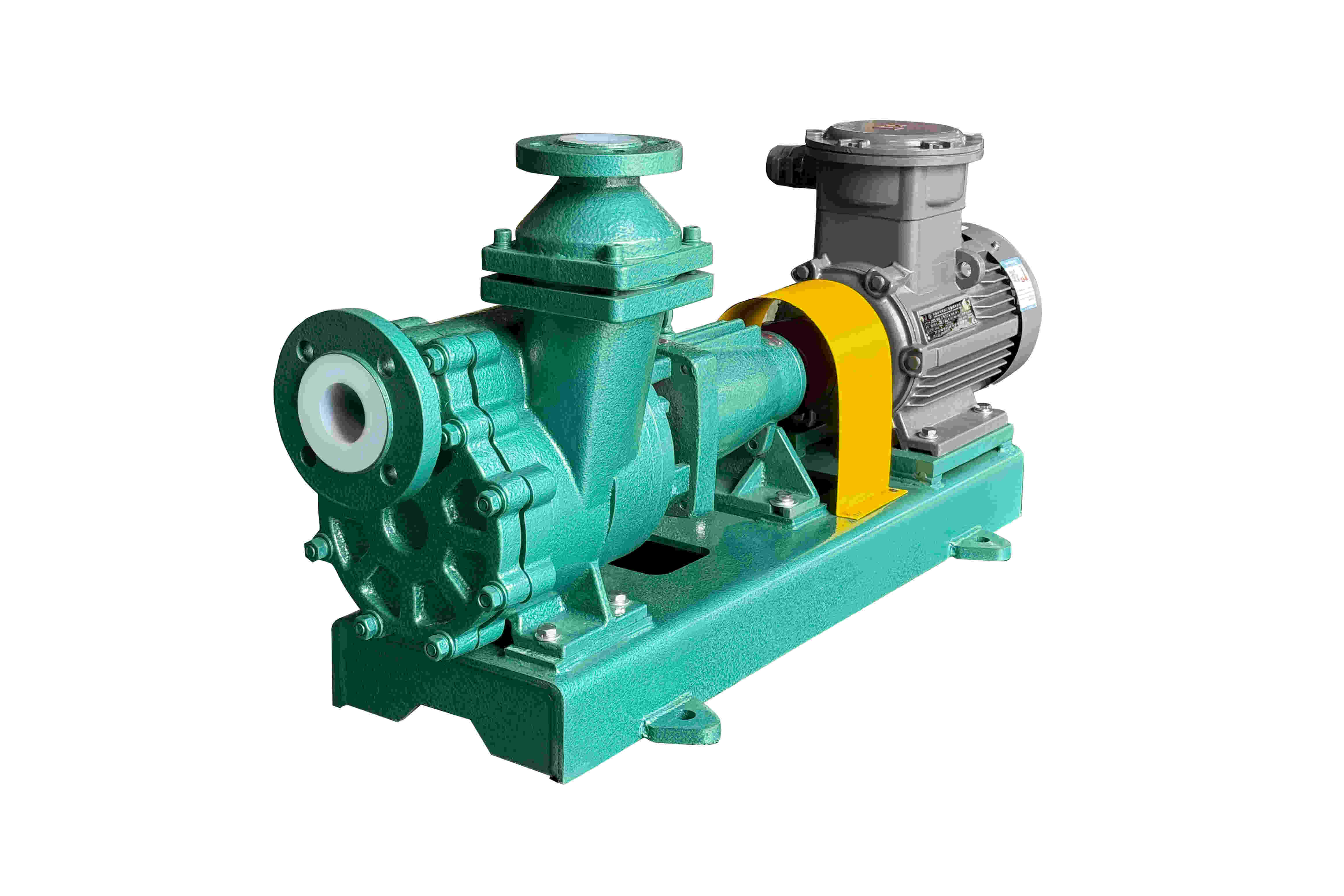

#Fluorine-lined centrifugal pumps are widely used in the transportation of highly corrosive media such as sulfuric acid, hydrofluoric acid, and organic solvents due to the excellent corrosion resistance of PTFE/PFA linings. Mechanical seals are core components for leakage prevention, and their replacement quality directly affects the life and safety of the pump. This article takes three typical media, 98% sulfuric acid, 40% hydrofluoric acid, and mixed organic solvents, as examples to explain the key points of operation.

I. General preparations

1. Safety protection

· Wear chemical protective clothing + mask (acidic medium) or organic solvent-resistant gloves (solvents)

· Set up a "maintenance" warning sign and confirm that the power supply is double disconnected

2. Pre-processing

· Close the inlet and outlet valves and drain the residual medium in the pump (sulfuric acid medium needs to be neutralized and rinsed with sodium carbonate solution)

· Use a special fluoroplastic cleaner to wipe the pump cavity to avoid metal tools scratching the lining layer

II. Key points for medium differentiation operation

Case 1: 98% concentrated sulfuric acid medium pump

· Special requirements: The sealing surface must be made of silicon carbide, and graphite rings are prohibited (sulfuric acid will cause graphite expansion and failure)

· Disassembly tips:

① Loosen the middle bolt of the pump cover first to prevent sudden splashing of sulfuric acid crystals

② Check whether the shaft sleeve has pitting caused by sulfuric acid corrosion, and replace it simultaneously if necessary

Case 2: 40% hydrofluoric acid medium pump

· Key steps:

① After disassembly, calcium gluconate gel is needed to neutralize residual fluoride ions

② The static ring must be filled with polytetrafluoroethylene, and the dynamic ring is recommended to be alumina ceramic

Case 3: Acetone/chloroform mixed solvent pump

·Precautions:

① Rubber #O-rings are prohibited, and perfluoroether rubber (FFKM) seals are used instead

② Thoroughly degrease with anhydrous ethanol before installation to prevent the solvent from dissolving the grease and contaminating the sealing surface

III. Standardized process for mechanical seal disassembly

1. Safety preparation stage

·Power off and lock (LOTO), and hang warning signs.

·Close the inlet and outlet valves and drain the medium in the pump (acid medium needs to be neutralized and flushed).

2. Coupling separation

·Remove the protective cover bolts and use the puller tool to disassemble the coupling (cast iron impellers need to be padded with wooden blocks to prevent cracking)

3. Pump body disassembly

·Symmetrically loosen the pump cover bolts and pull out the motor and impeller assembly as a whole.

·Large pump bodies need to use the pump cover screw holes to push out the impeller

4. Removal of seal assembly

·Remove the impeller nut with a socket wrench and pull out the impeller axially (threaded impeller needs to rotate counterclockwise)

·First remove the dynamic ring assembly, and then use non-metallic tools to pry out the static ring (protect the O-ring)

IV. Key steps for mechanical seal installation

1. Pretreatment

·Clean the shaft sleeve, sealing chamber and new seal with acetone

·Check that there are no scratches on the mirror surface of the dynamic and static rings and no deformation of the spring

2. Installation of static ring

·Press the static ring vertically into the sealing chamber to ensure that the anti-rotation pin is in the groove (clearance 0.1-0.2mm)

3. Assembly of dynamic ring

·Apply silicone grease before the dynamic ring assembly is inserted into the shaft, and adjust the spring compression according to the manufacturer's standard

4. Reinstall the whole assembly

·After the impeller is installed, manually turn the wheel to check that there is no friction sound

Tighten the pump cover bolts in diagonal order in batches (torque refers to GB/T 16823.1)

V. High-frequency operation risk tips

·Acid medium pump: HF pump needs to be neutralized with calcium gel after disassembly, and graphite seal is prohibited for sulphuric acid pump

·Solvent pump: FFKM O-ring must be used, and ethanol degreasing must be performed before installation

·Common taboos: It is forbidden to knock on the end face of the static ring, and the dynamic ring should automatically rebound ≥3 times after compression

VI. Test acceptance standards

1. After the point-to-point test is correct, it should run continuously for 30 minutes

2. Leakage control:

·Water medium ≤5 drops/minute

·Corrosive medium ≤3 drops/minute

VII. High-frequency maintenance questions and answers

Q: Why is the double-end face machine seal more recommended for fluorine-lined pumps?

A: Isolation fluid can be added to form a protective barrier, which is especially suitable for permeable media such as hydrofluoric acid

Q: How to deal with vibration exceeding the standard after the machine seal is replaced?

A: First check the dynamic balance of the impeller and the bending of the shaft, and then confirm that the verticality of the static ring installation is ≤0.05mm

In summary, the replacement and maintenance of the mechanical seal of the corrosion-resistant pipeline pump is crucial to ensure the normal operation of the equipment. Users must not only master the correct replacement method, but also carefully follow the relevant precautions to extend the service life of the equipment and improve production efficiency.

Read More