Jun 17, 2025

This article analyzes the available pump types for specific media to help you make a faster and more effective selection, and also provides some data for your reference.

1.Working condition characteristics analysis

Medium characteristics

Strong acidity: pH=2 is a strong acid environment, and the acid corrosion resistance of the material needs to be considered

Oxidation: The medium has oxidizing properties, and the material's antioxidant capacity needs to be evaluated

Containing solid particles: The presence of small sand particles will cause wear problems (it is recommended to confirm the particle size distribution and concentration)

2.Material selection

2.1 It is recommended to use PTFE (polytetrafluoroethylene) or F46 lined pump body, which has the following features:

✓ Strong acid resistance (applicable to the full range of pH 0-14)

✓ Excellent oxidation resistance

✓ Smooth surface and not easy to scale

2.2 Mechanical seals are recommended to use SiC/SiC pairing, which is more resistant to particle wear than graphite

2.3 Key selection parameters

Required notes Speed ≤ 2900rpm: reduce particle erosion and wear

Impeller type semi-open/open impeller: avoid blockage of closed impeller flow channel

Gap design is 0.3-0.5mm larger than standard pump to accommodate particle passage

Shaft seal type: double-end mechanical seal + flushing water (Plan53B external flushing solution is recommended)

3. Special design points

Wear-resistant structure

The impeller front cover is thickened by 2-3mm

A replaceable wear-resistant plate is set at the volute of the pump body

The surface of the flow-through parts can be hardened

4. Operation suggestions

It is recommended to install a Y-type filter at the inlet (the mesh size is determined by the particle size)

The minimum flow rate should be >30% Qn to prevent solid deposition

The flow channel should be flushed in time when the machine is shut down

5. Recommended typical models

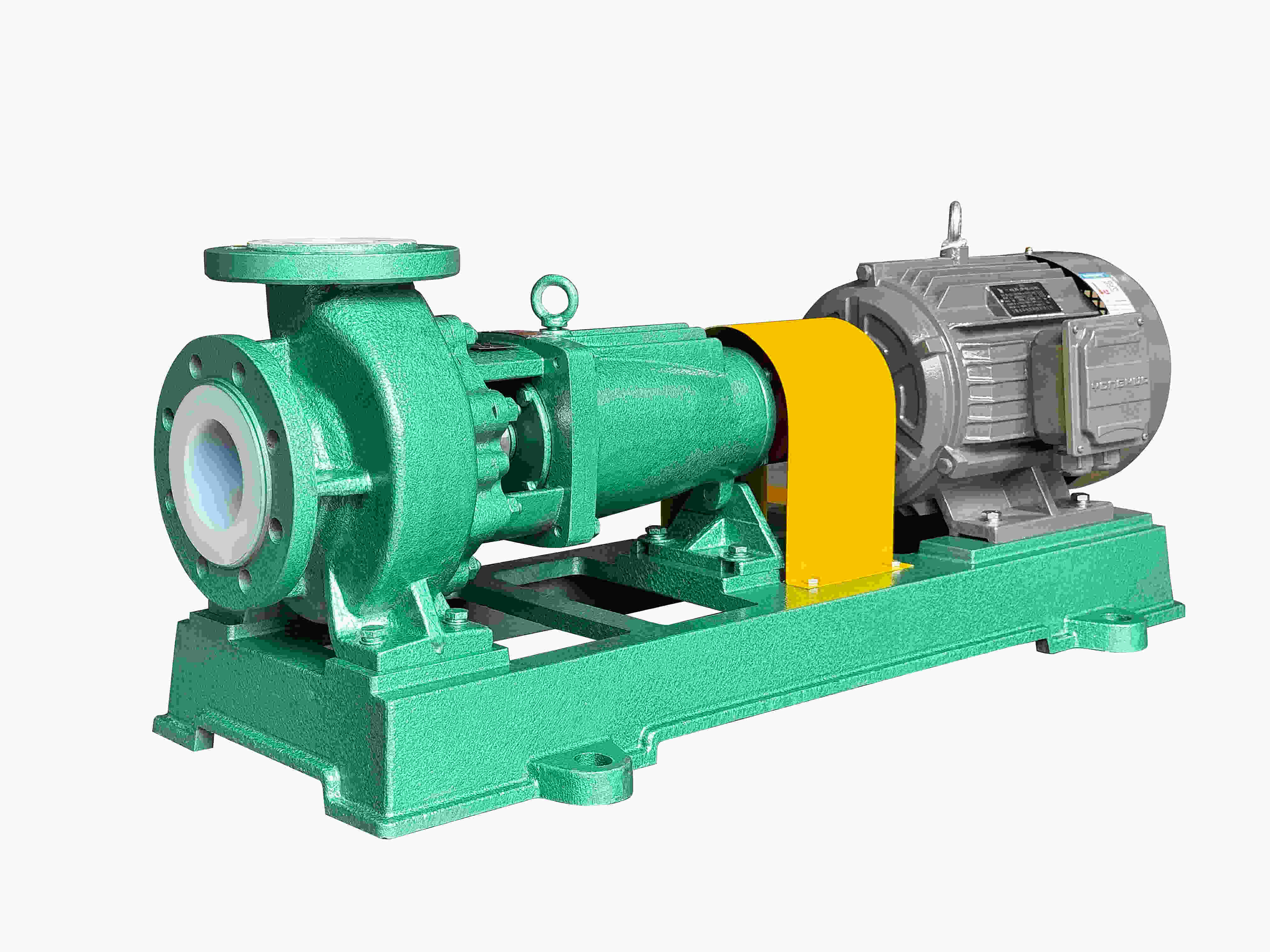

Domestic: IHF80-65-160 fluoroplastic centrifugal pump (with wear-resistant modification kit)

Imported: CPK80-200F (with impeller for granular media)

If the budget is li mited, you can consider: FSB80-50-200 (need to confirm the actual particle parameters)

If you have better ideas, please leave a message. We are happy to learn new knowledge and provide better service.

Attached is the performance curve of our IHF chemical pump:

Read More