FSB series horizontal fluorine-lined industrial hydrochloric acid pumps use a perfluorinated pump body design, which is suitable for use in environments with acid mist. It will not corrode the pump body, has a simple structure and is easy to use.

Flow Range :

3~100m³/hHead Range :

15~50mPower :

1.5`18.5KwTemperature :

-20-120℃Horizontal Fluorine-Lined Industrial Hydrochloric Acid Pump

FSB pumps have the following design features:

FSB Series Fluorine Alloy Centrifugal Pumps Applications:

Suitable for conveying hydrochloric acid of different concentrations at -20-110℃. Please consult our technical staff for specific selection.

Precautions For Use:

We can according to actual working condition, choose different configuration, provide an accurate solution. Technical consulting, please contact us!

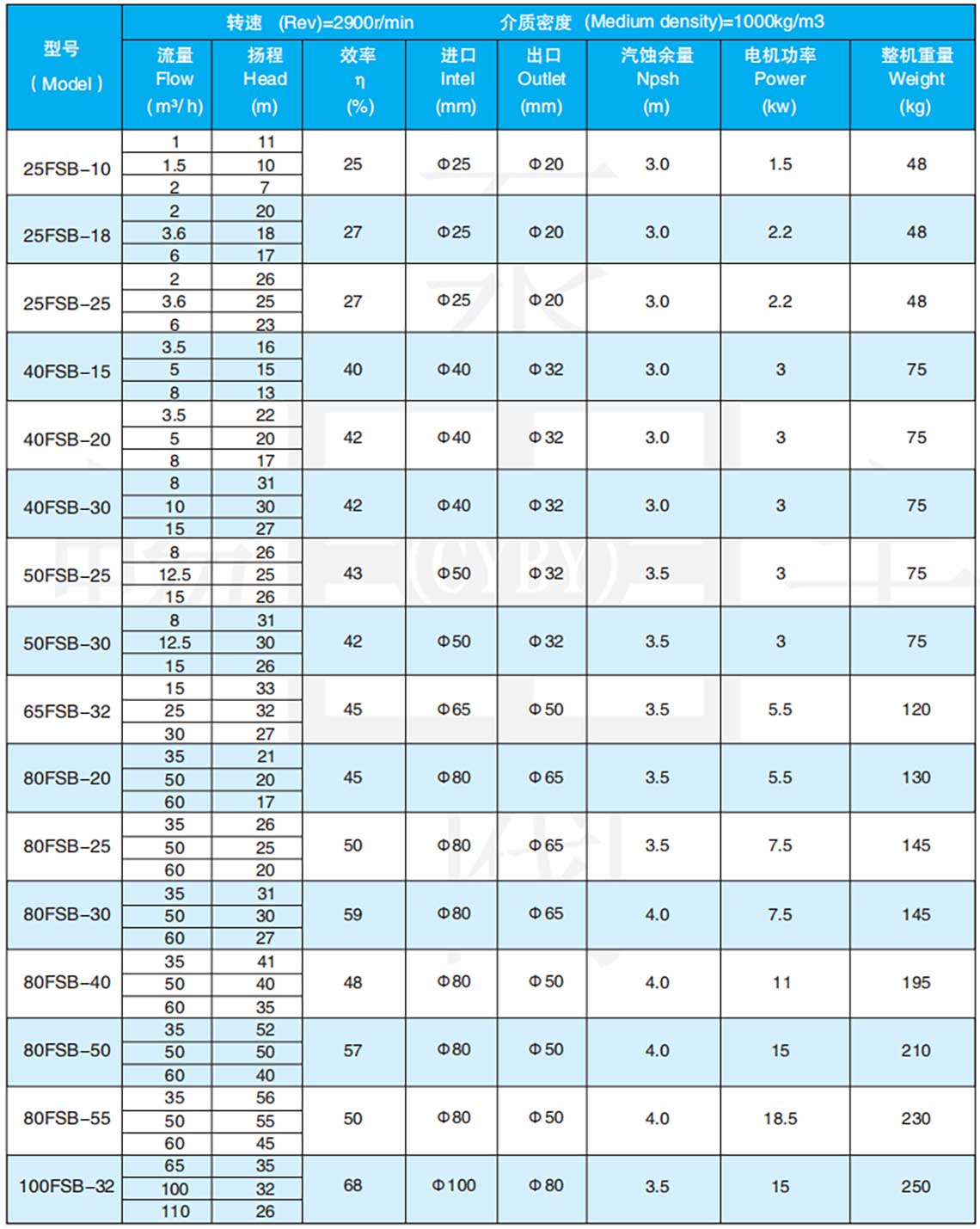

1: Selection table

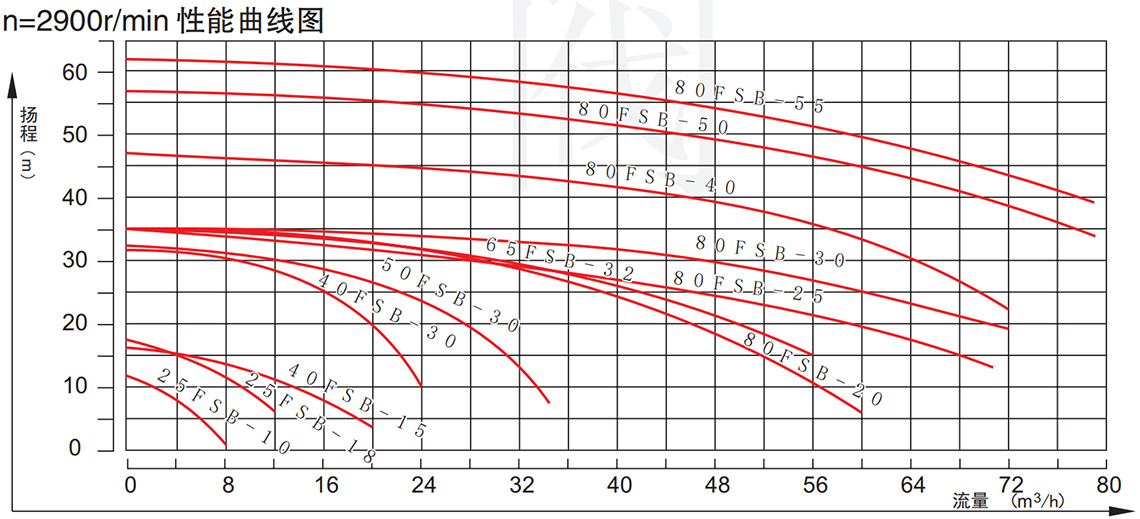

2: Performance curve

FAQ

1. What is a slurry pump used for?

A slurry pump is used for transferring and handling mixtures of liquid and solid materials, known as slurries. It is commonly used in industries such as mining, construction, and wastewater treatment to move abrasive, viscous materials like:

Slurry pumps are designed to withstand the abrasive nature of these materials, ensuring efficient and reliable operation.

2.What is the difference between a slurry pump and a water pump?

A slurry pump is designed to handle mixtures of liquid and solid materials, making it suitable for transferring abrasive and viscous slurries. In contrast, a water pump is used primarily for moving clear water or low-viscosity liquids. Slurry pumps have stronger construction and specialized impellers to withstand wear from solid particles, while water pumps focus on efficiency and flow rate for fluid transfer.

3.Can slurry pump pump water?

Yes, a slurry pump can pump water, but it is primarily designed for transferring slurries that contain solid particles. While it can handle clean water, using a slurry pump for this purpose is generally not as efficient as using a dedicated water pump. If only water needs to be pumped, a water pump is usually the better choice for optimal performance.

4.What is the disadvantage of slurry pump?

The main disadvantage of a slurry pump is that it can be more expensive to operate and maintain than standard pumps due to its heavy-duty construction and wear on components from abrasive materials. Additionally, slurry pumps may have lower efficiency when handling clear liquids compared to dedicated water pumps. They also require more frequent maintenance to ensure optimal performance and prevent damage from solid particles.

5.How long do slurry pumps last?

Slurry pumps typically last between 5 to 15 years, depending on several factors such as the quality of the pump, the materials being pumped, the operating conditions, and the level of maintenance. Proper maintenance and regular inspections can help extend the lifespan of a slurry pump and improve its overall performance.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)