The HD Chemical Drum Pump, also known as an oil barrel transfer pump, is designed for stable performance, user-friendly operation, and reliable quality at a competitive cost. All critical components utilize imported parts—including deep groove ball bearings, VT fluororubber seals, TFEP fluoropolymer oil seals, and shaft sleeves from Switzerland, Japan, and Taiwan. This guarantees authentic materials and structural durability, providing customers with consistently high reliability and long service life.

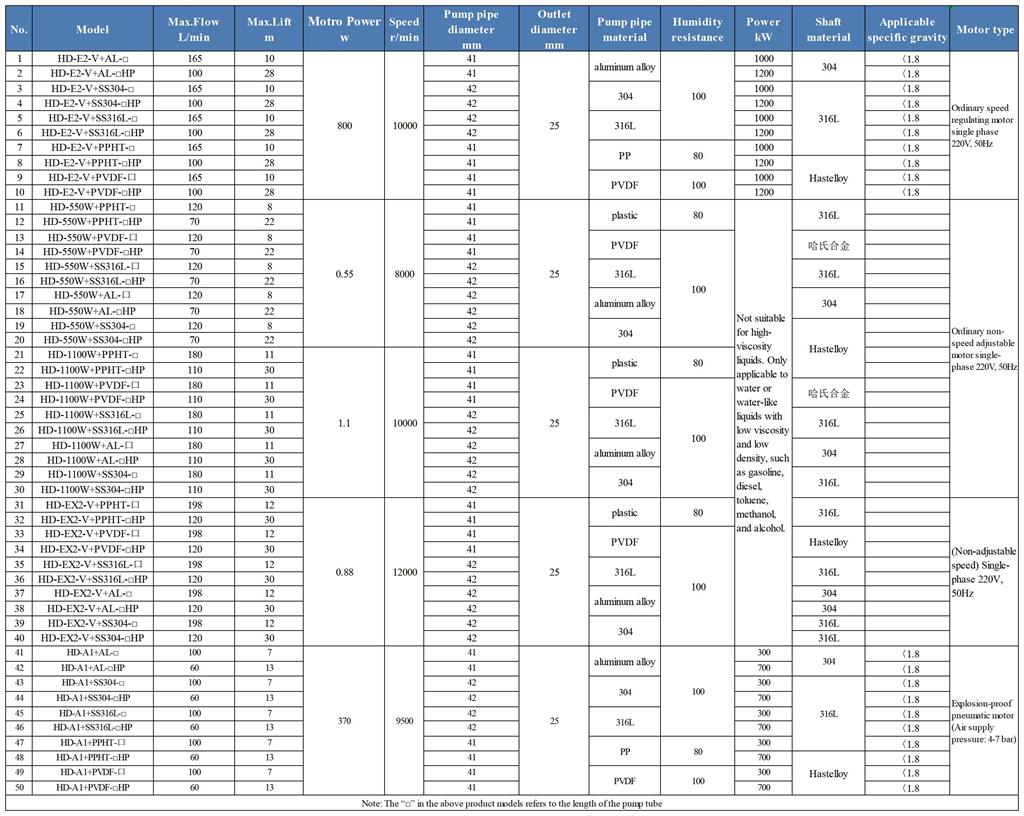

Flow Range :

Maximum 198 L/minHead Range :

Maximum 30 mTemperature :

Speed: 0-12,000 r/minMaterial :

304, 316L, PVDF, PP, Aluminum Alloy, Hastelloy, Plastic, HastelloyThe HD Chemical Drum Pump is specifically designed for safe and efficient operation, making it ideal for transferring various corrosive chemicals, oils, and solvents from drums and containers. It features a robust construction with chemically resistant PTFE and fluororubber fluid passages. Designed with operator safety in mind, it incorporates leak-proof design and spark-free operation mechanisms, making it suitable for volatile environments. Whether in industrial manufacturing, laboratories, or waste management applications, the HD Chemical Drum Pump provides a reliable and cost-effective solution for safe fluid management.

The Chemical Drum Pump primarily consists of core components such as the pump tube, motor/pneumatic drive head, impeller, discharge port, and sealing assembly, which collectively ensure safe and efficient transportation of chemical liquids. Below is an overview of the features of each component:

For specific material or design recommendations tailored to your application, please contact our technical support team.

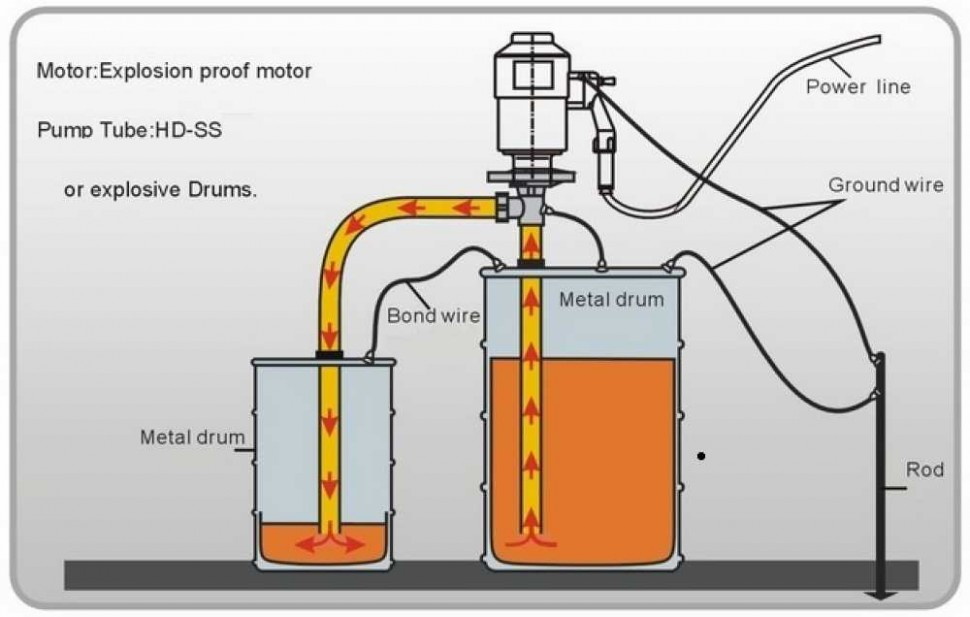

The Chemical drum pump is driven by an electric or pneumatic motor, which causes the impeller inside the pump to rotate at high speed. Centrifugal force is used to draw oil from the bottom of the container into the pump pipe, where it is accelerated by the impeller. The kinetic energy of the liquid is converted into stable pressure within the pump chamber and then discharged through the outlet, achieving efficient transportation. The entire system employs a seal-less design, eliminating the risk of leakage and ensuring safe, clean, and cost-effective transfer of oil and viscous media (such as lubricating oil, fuel, etc.). Taking the oil drum pump as an example, here is how it works:

Comprehensive leak-proof design

Features a shaftless design and leak-free pump tube structure to eliminate leakage risks, making it particularly suitable for transporting corrosive, flammable, explosive, and high-purity liquids, ensuring operational safety.

Multiple Materials and Models Available

Offers a variety of pump tube materials, including polypropylene, PVDF, PTFE, stainless steel, and aluminum alloy, to meet the compatibility requirements of the chemical industry. Suitable for low, medium, and high viscosity liquids, it can be widely used in over 80% of industrial applications.

Highly efficient and lightweight, easy to operate

The entire unit is lightweight and highly maneuverable, capable of quickly emptying a 200-liter standard drum in 2-3 minutes. Equipped with quick-connect interfaces and a modular structure, assembly and disassembly can be completed without tools, significantly improving maintenance and operational efficiency.

Supports multiple power drive options

Available with electric (with speed control and overload protection) or pneumatic drive options, adapting to different on-site power conditions and providing more flexible equipment configuration solutions.

Compatibility design

Standard interface design compatible with various hoses and connectors; improved couplings require no alignment and can be quickly connected, suitable for a wide range of fluids from ordinary media to strong acids and alkalis.

Reliability and ease of maintenance

Each pump undergoes rigorous factory testing and supports short-term dry running without damage. The modular structure makes maintenance and disassembly more convenient, with disassembly and reassembly completed within 10 minutes, while providing a wide range of accessories to meet diverse needs.

Drum Chemical Pump is primarily used in the following industries and scenarios:

Changyu Pumps is a manufacturer and supplier of chemical drum pumps.We support configuring suitable chemical drum pump solutions for different containers. Whether it's standard tanks, industrial drums, IBC containers, or various non-standard special containers, immersion depth directly affects pumping performance and operational safety. Common immersion requirements include 500 mm, 700 mm, 1000 mm, and 1200 mm, with multiple standard pump tubes available for selection, offering strong adaptability and ready availability.

For special depth or non-standard container scenarios, such as deep-bottom storage tanks, custom tank bodies, or pump pool structures, Changyu can provide customized pump tube solutions with lengths ranging from 300mm to over 3 meters, precisely matching your actual operating conditions and equipment requirements. For further information on standard selections or customized solutions, please feel free to contact our technical team to obtain tailored pumping solutions and product details.

If you require further information on specific applications or product selection, please feel free to consult our professional technical team.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)