Maintenance is critical to the day-to-day operation of a centrifugal pump. This article systematically explains the maintenance of centrifugal pumps from four key aspects:

Part I: Benefits of regular maintenance

1.1 Extend service life

- Reduce mechanical wear by lubricating, cleaning and replacing wearing parts

1.2 Improve operating efficiency

- Regularly check and adjust the impeller/seal to ensure that the flow and head meet the design specifications

1.3 Reduce failure rate

- Timely replacement of bearings/seals/couplings can prevent small problems from escalating

1.4 Cost optimization

- Reduce energy consumption by optimizing operation

1.5 Safety assurance

- Stable operation can minimize safety hazards

1.6 System stability

- Maintain stable pressure/temperature parameters

1.7 Environmental compliance

- Prevent leakage to meet regulatory requirements

1.8 Improve reliability

- Predictive maintenance through data analysis

1.9 Minimize downtime

- Perform regular maintenance without interrupting production

1.10 Performance optimization

- Prevent efficiency loss deposition caused by internal failures

Part II: Working principle of centrifugal pumps

2.1 Main components

- Impeller: transfers energy through curved blades

- Volute: converts kinetic energy into pressure energy

- Shaft: transmits motor power

- Seals: prevents leakage

2.2 Operation process

- Filling: liquid enters through the suction pipe

- Centrifugal acceleration: rotating impeller (1,500-3,500 RPM) transmits kinetic energy

- Energy conversion: the volute design converts 60-75% of kinetic energy into pressure

- Discharge: pressurized liquid is discharged through the delivery pipe

2.3 Energy transfer chain

Electric energy → rotational kinetic energy → fluid kinetic energy → pressure energy

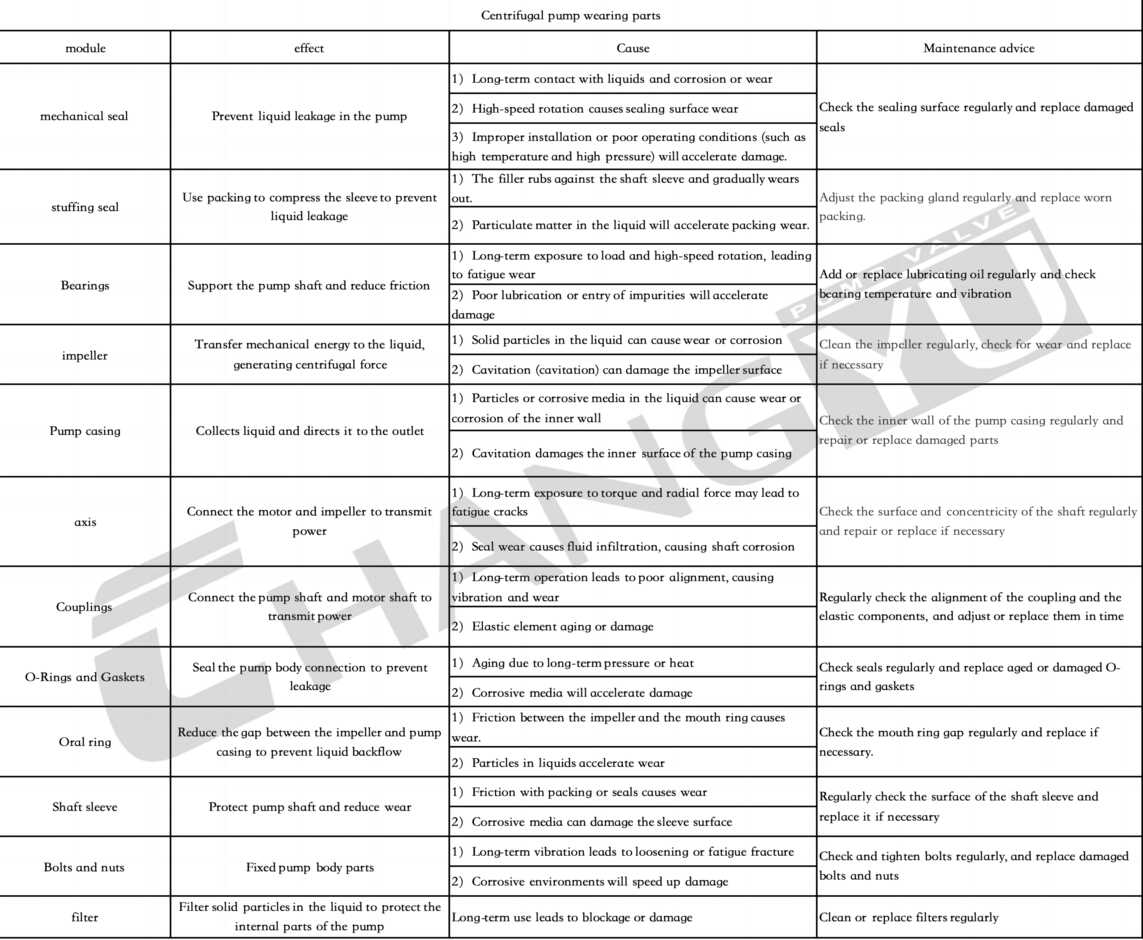

Part III: Consumable parts

Part IV: Maintenance procedures

4.1 Daily inspection

Based on the above statements, daily regular inspection is undoubtedly the first and most critical part of centrifugal pump maintenance. During the maintenance process of the centrifugal pump, by observing the vibration of the pump, we can find abnormalities from the swing amplitude of the centrifugal pump during operation. Excessive swing often means adjustments or repairs are needed. At the same time, it is equally important to listen to the sound of the water pump when it is running. Significant noise is often a sign of damage.

When checking the pump body, motor and connecting shaft parts, pay close attention to whether there is oil leakage, water leakage or loose screws at the connection parts. In addition, it is necessary to regularly check the impeller pressure gauge, blade temperature monitor and other equipment, which can directly reflect the working status of the pump.

After eliminating the obvious faults on the surface, regular cleaning is essential to maintain the efficient operation of the centrifugal pump.

Cleaning work

We must not only ensure the cleanliness of the pump body and motor housing, but also regularly clean the inside of the pump cavity to thoroughly remove dirt and impurities. This measure can not only significantly improve the operating efficiency of the pump, but also effectively prevent clogging and corrosion problems, thereby extending the service life of the pump. Through such maintenance, we can ensure that the centrifugal pump continues to provide stable support for the production system.

Lubrication supplement:

Oil lubrication: Since traditional mechanical transmission methods are difficult to provide effective lubrication, fat-soluble light oil must be used for lubrication. As one of the key components of the centrifugal pump, good lubrication can significantly reduce wear and extend the service life of the bearing. Therefore, we should regularly replenish or replace the lubricating oil according to the lubrication method. Considering that the blade material of centrifugal pumps may be prone to hardening, it is also recommended to change the light oil regularly.

Replacement of seals:

Seal protection: The centrifugal pump is equipped with sealing measures inside to ensure that the liquid will not leak and impurities will not mix in. In daily maintenance, these parts should be checked and cleaned regularly to prevent leakage. When the seal is severely worn, it should be replaced in time to ensure the sealing performance of the pump.

Of course, during the long-term shutdown of the centrifugal pump, the medium in the pump must be emptied, antifreeze measures must be taken, and dust and moisture prevention treatment must be done. At the same time, it is crucial to establish detailed maintenance records. This not only helps us understand the operating status of the pump in real time and predict possible failures, but also provides an important reference for future maintenance work.

To sum up, the maintenance of centrifugal pumps is a systematic and meticulous work.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)